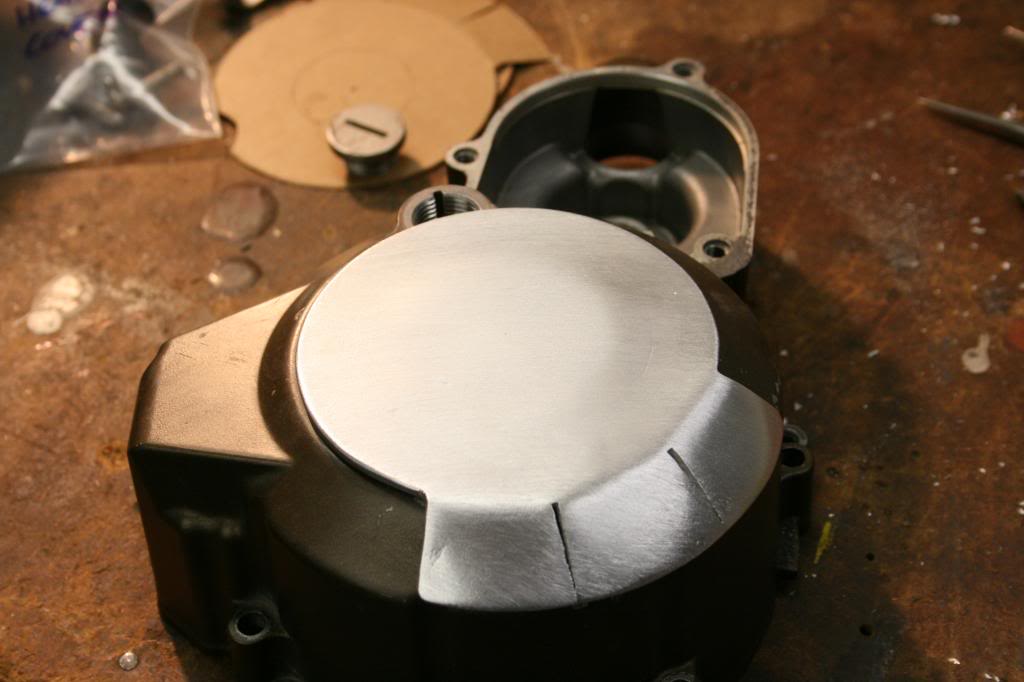

Stator cover protector

#1

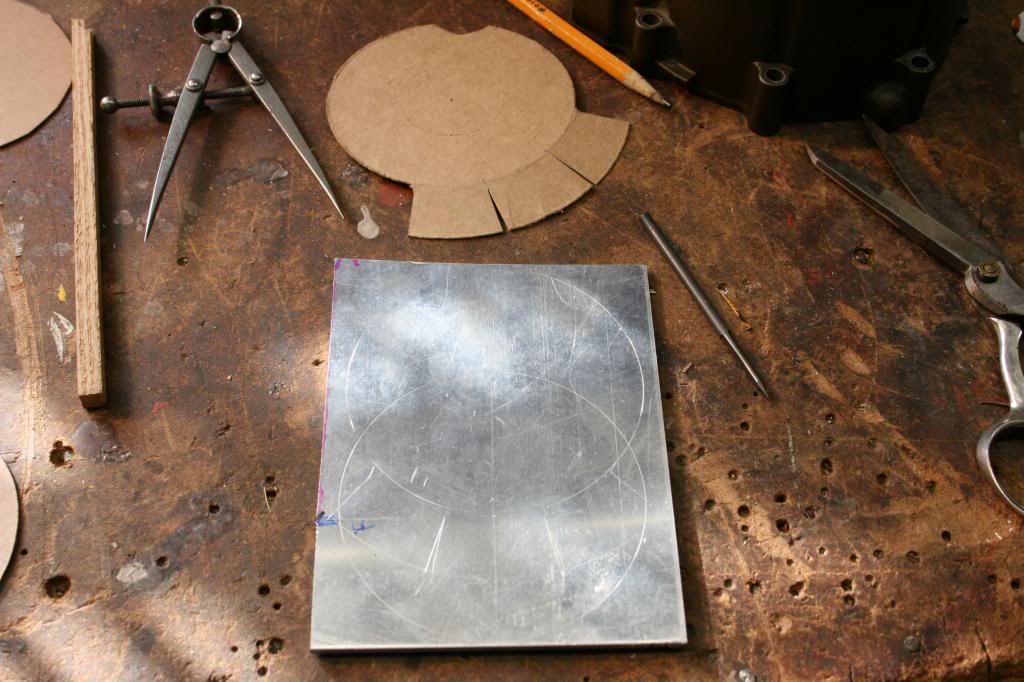

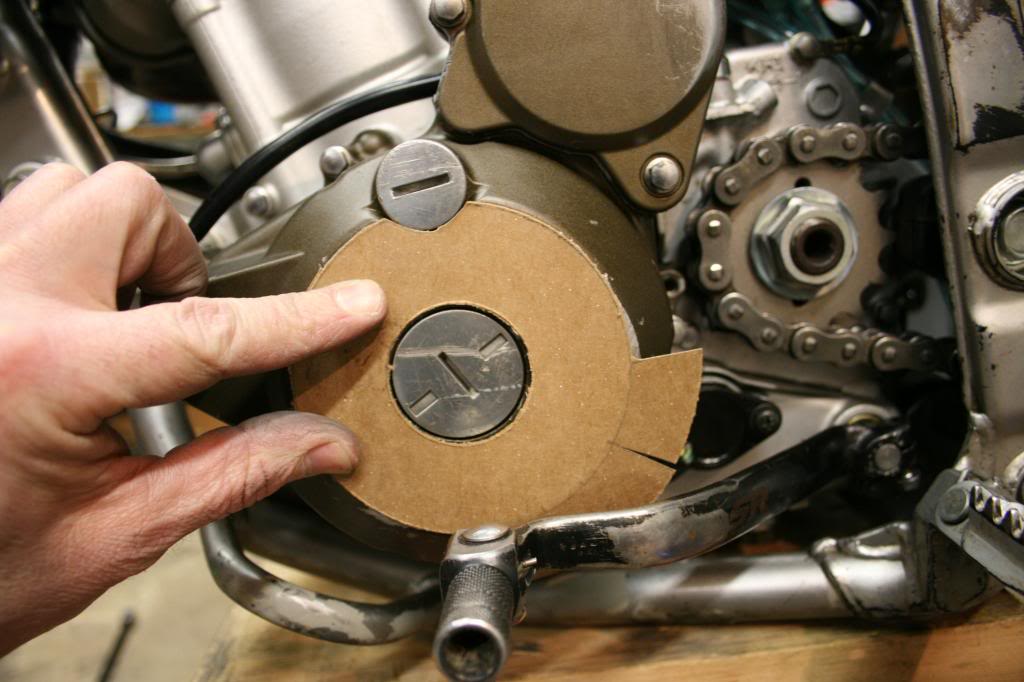

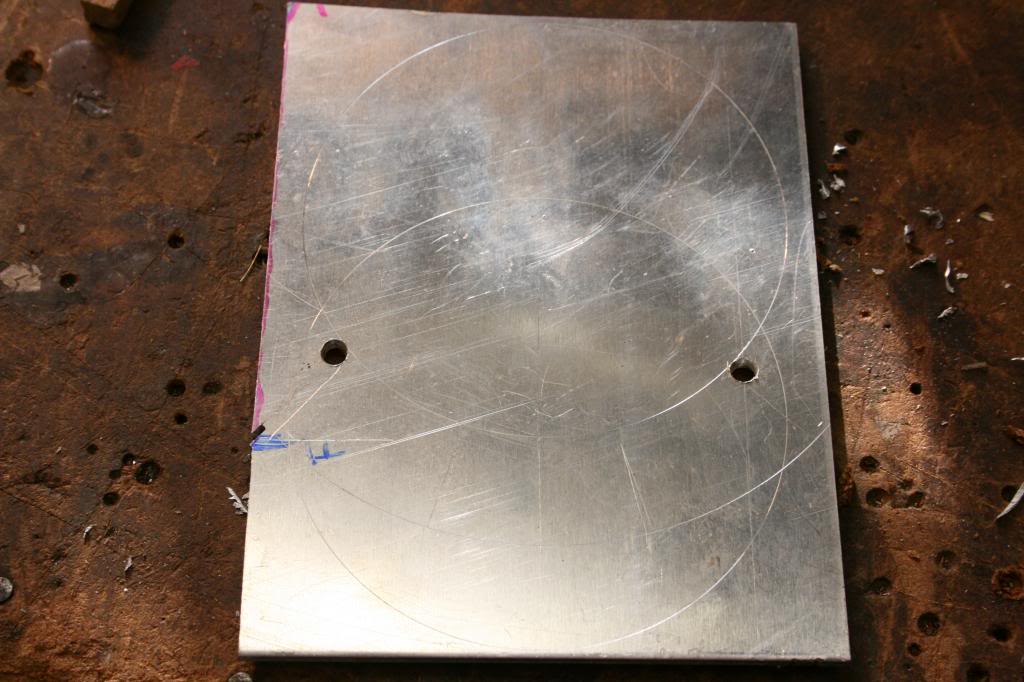

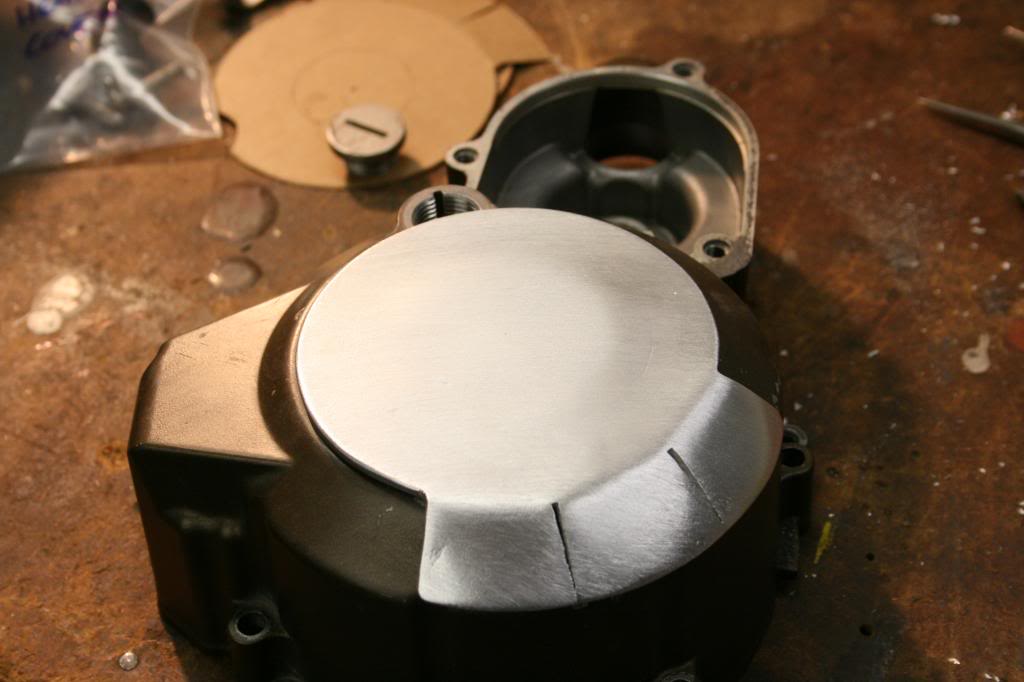

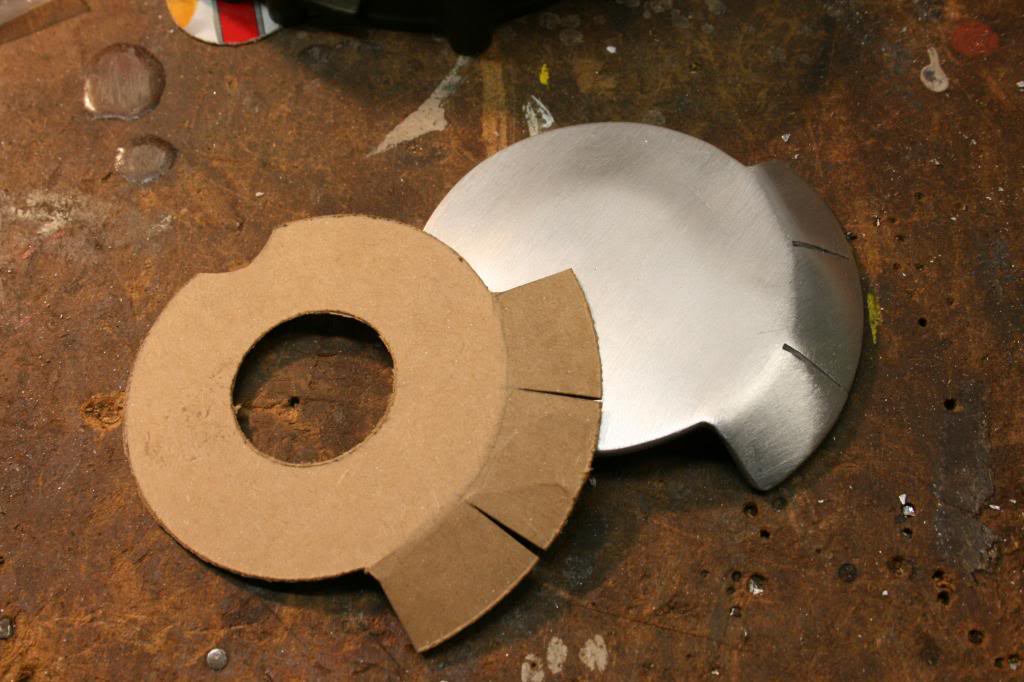

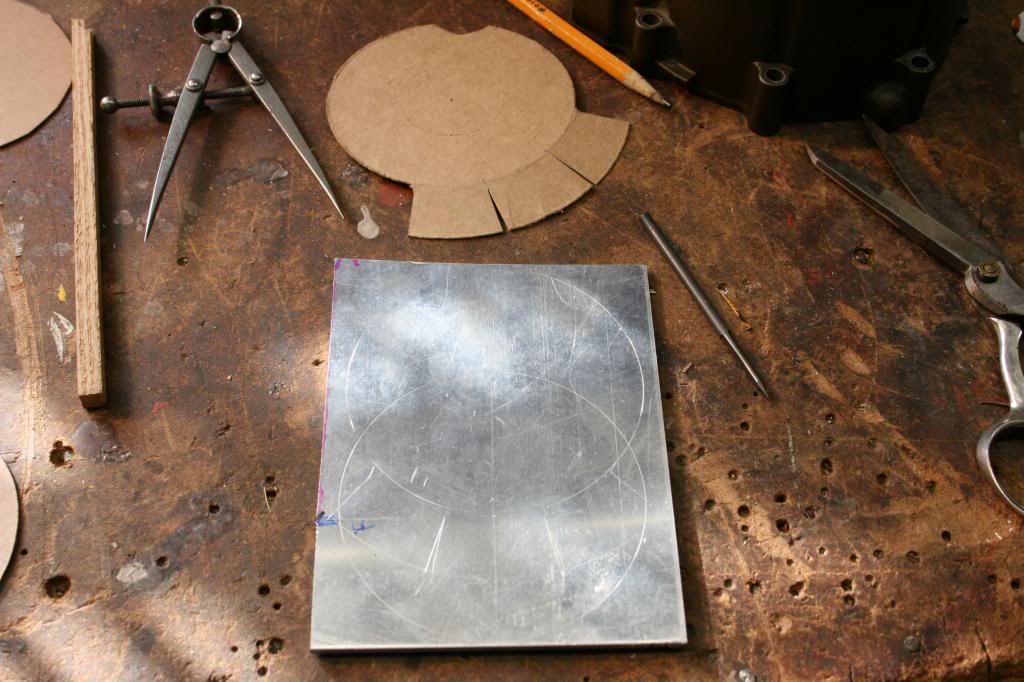

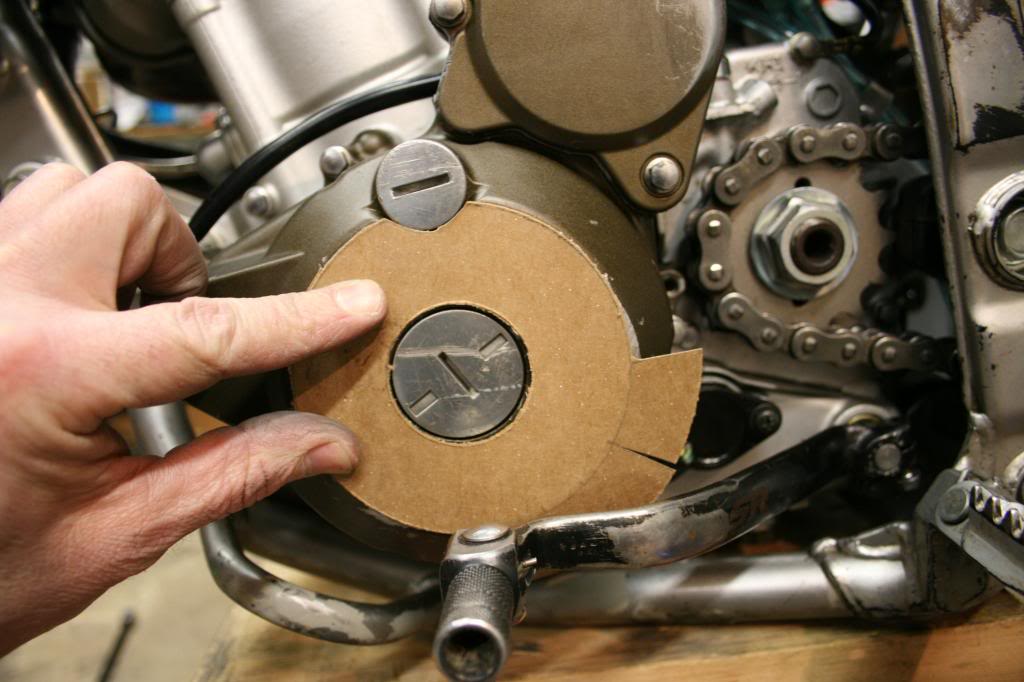

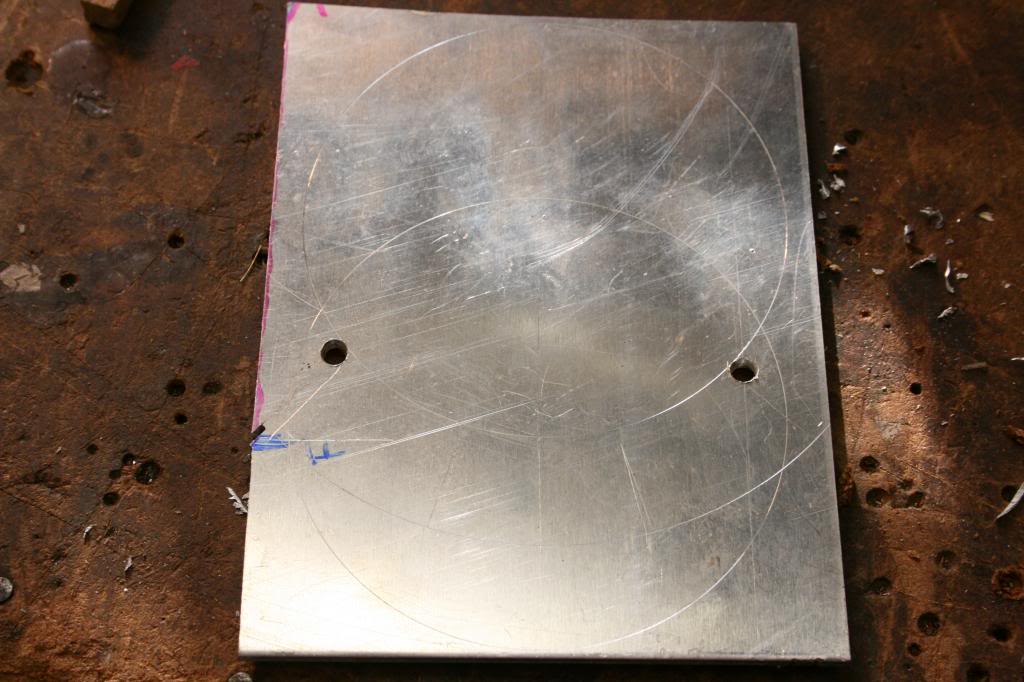

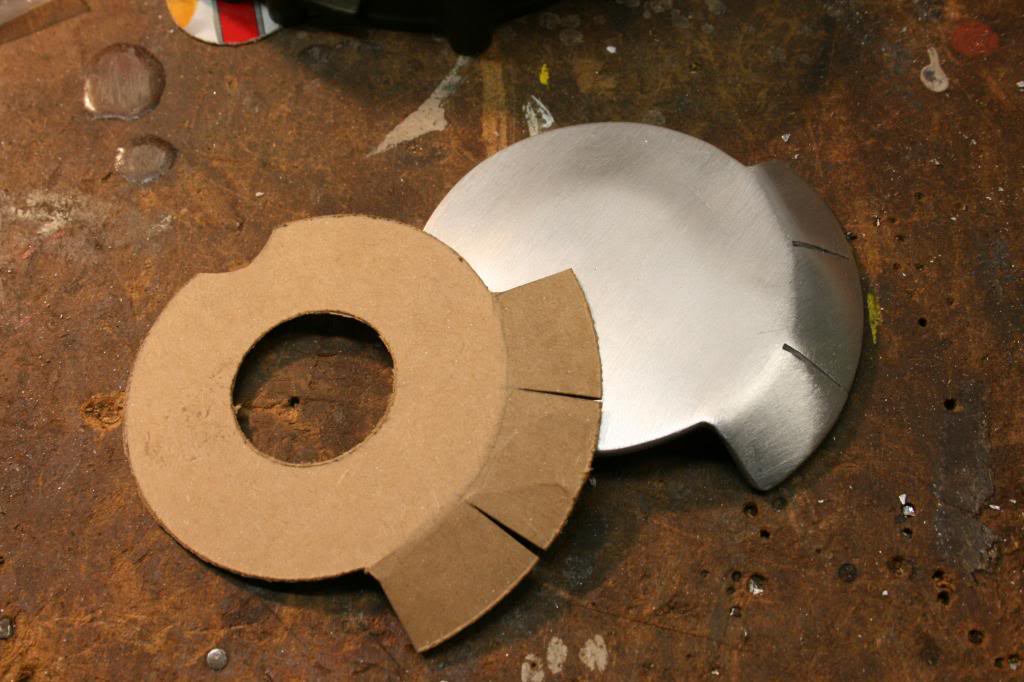

The used stator cover I bought off eBay for my recent engine re-build has a nasty gouge in it. My old stock one had a pretty good one in it too. I've seen many othrers with shifter gouges in them. I looked but haven't been able to find anything aftermarket for a case protector so I decided to try and make one. I still have some .125 aluminum left from my skidplate project. I started by making a template out of a piece of Cheezit box. Pictures can tell most of the story.

Still need to figure out how I'm going to attach it. Many of these things are attached with Velcro. but I'm thinking I'd like something tougher. I may cut out the access holes so I can get to the flywheel and timing mark with out removing the guard, and then mount it with some double sided tape like the GoPros use.

Still need to figure out how I'm going to attach it. Many of these things are attached with Velcro. but I'm thinking I'd like something tougher. I may cut out the access holes so I can get to the flywheel and timing mark with out removing the guard, and then mount it with some double sided tape like the GoPros use.

Last edited by dan888; 02-24-2013 at 01:29 AM.

#3

Alright dan...I realize you're in the frozen northern tundra, but please...step back from the motorcycle. Take a deep breath...drink some hot chocolate...clear your cabin-fever-infested mind for a minute. BTW...you haven't chopped up any family members or the family pet yet, have you? I realize that severe cabin fever does strange things. Ever see "The Shining". Your needless project here is obvious evidence of a mental breakdown brought on by 20 feet of snow and extreme temps. That basement gets really small in the dead of winter, doesn't it, dan....LOL!

But seriously, the way you ride, dan, you need all the rubber covered, heavily armored protection you can get. Do you think double-sided tape will hold that with the engine heat? It's too bad you couldn't somehow incorporate the rotor bolt cover in some way. You always do good stuff with aluminum, dan.

But seriously, the way you ride, dan, you need all the rubber covered, heavily armored protection you can get. Do you think double-sided tape will hold that with the engine heat? It's too bad you couldn't somehow incorporate the rotor bolt cover in some way. You always do good stuff with aluminum, dan.

#7

Thanks guys.

TNC Just for fun I decided to rebuild my entire engine this winter,but I got it done too quickly, and now i need some other silly busy work. ...... The family is fine.

Seriously though, I am ready for some warm weather and riding. We got a 60 degree day about 2 weeks ago and that felt really good. Snow and ice on the ground now

That is a good point about the temperatures and the two sided tape. The 3M VHB stuff they sell with the GoPro is crazy tough but I will have to check the temp tolerance.

I thought about attaching the cover with machine screws, but decided that I didn't want to weaken the stator cover by drilling holes in it.

Darkmarc the RTV is an option, but I don't want to lose the cover, and silicone isn't as tough as I might want. It may be the compromise I end up going with thogh .

Wildcard I would like to leave the witness holes covered for added protection. That means I will have to take the new cover on and off to check the valves. I am considering making the access holes in the cover so I could mount it more permanently. Welding sounds good but I have been told that welding cast aluminum is a different game?

Dan

TNC Just for fun I decided to rebuild my entire engine this winter,but I got it done too quickly, and now i need some other silly busy work. ...... The family is fine.

Seriously though, I am ready for some warm weather and riding. We got a 60 degree day about 2 weeks ago and that felt really good. Snow and ice on the ground now

That is a good point about the temperatures and the two sided tape. The 3M VHB stuff they sell with the GoPro is crazy tough but I will have to check the temp tolerance.

I thought about attaching the cover with machine screws, but decided that I didn't want to weaken the stator cover by drilling holes in it.

Darkmarc the RTV is an option, but I don't want to lose the cover, and silicone isn't as tough as I might want. It may be the compromise I end up going with thogh .

Wildcard I would like to leave the witness holes covered for added protection. That means I will have to take the new cover on and off to check the valves. I am considering making the access holes in the cover so I could mount it more permanently. Welding sounds good but I have been told that welding cast aluminum is a different game?

Dan

Last edited by dan888; 02-24-2013 at 01:40 PM.

#8

How hot do you think the stator cover gets? I would think it has to be under 200 degrees.

3M Scotch 4950 VHB Tape (45 mil / general purpose) Specifications

Adhesive: general-purpose acrylic How are adhesives different?

Carrier/Backing: closed-cell acrylic foam (firm)

Release Liner: white paper (printed)

Thickness: 48 mils (carrier, adhesive) 45 mils (carrier) 3 mils (liner) What is a mil?

Adhesion: 400 ounces per inch (to stainless steel)

Tensile Strength: 140 pounds per inch (longitudinal)

Application Temperature: 50°F to 100°F

Service/Operating Temperature: up to 200°F

Density: 50 pounds per cubic foot

Dynamic Overlap Shear: 80 pounds per square inch

Short Term Temperature Resistance: up to 300°F