Setting up timing chain problem

#1

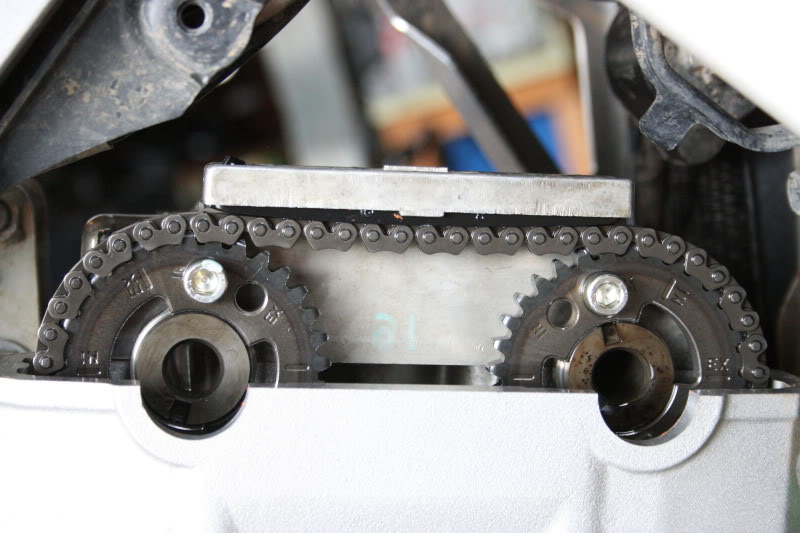

well i have turned the crank to the t point. i do acually ntoice a d poitn also. my prolem is when i seem to put the exhuast cam in place the only place the arrows line up on the engine are in the middle of the link not inbetween like it should. i counted 32 back from the exhust to intake. i tried djusting crank to make sure it was center multi times i get same results. any help is appericated thank guys.

i have some pics showing it. below in links thank you

http://img413.imageshack.us/i/img0225ny.jpg/

http://img59.imageshack.us/i/img0226ez.jpg/

http://img101.imageshack.us/i/img0227qu.jpg/

i have some pics showing it. below in links thank you

http://img413.imageshack.us/i/img0225ny.jpg/

http://img59.imageshack.us/i/img0226ez.jpg/

http://img101.imageshack.us/i/img0227qu.jpg/

Last edited by TweakInSleep; 09-19-2010 at 04:38 AM.

#2

I don't know how the 250 is set up, but on the 650 there are two lines marked opposite each other on each cam sprocket. With the engine rotated to the top dead center (TDC) mark on the stator flywheel (marks are seen through the top smaller hole on the stator side cover) at the T mark, shown a bit closer in the little round inset picture:

these two lines on the cam sprockets are lined up in line with the top of the head like below.

This is an example from a KLR. The timing has nothing to do with the chain links, only how the cams line up at top dead center (TDC). That simple. If the KLX250 is similar to the KLR and KLX650 the setup will be the same, but in mirror image on the cam sprocket head alignment sinceyou will be working from the other side of the engine while lining up the marks, since the cam drive is opposite that of the KLR and KLX650.

Based on your pictures they use the same sprockets on intake and exhaust, but use different marks labeled for which ever cam the sprocket is on. Be sure to pay attention to that marking. Get a look at a manual before you go any further to make sure how to do the work. Without a manual I can not precisely say the above method is right, but I'm thinking it is based on the pictures. If you have the crank at the T mark the cams look out of position, but again I do not know without actually looking at a shop manual to be sure it is supposed to be at the T mark and both cam lobe sets off the valves (valves closed, compression stroke) or not. Don't play around, get a look at a manual or if someone else here can confirm what I am saying, otherwise you're taking a risk. Maybe consider sending a PM to TNC. I believe he knows for sure. Others here do too, but I don't know them.

these two lines on the cam sprockets are lined up in line with the top of the head like below.

This is an example from a KLR. The timing has nothing to do with the chain links, only how the cams line up at top dead center (TDC). That simple. If the KLX250 is similar to the KLR and KLX650 the setup will be the same, but in mirror image on the cam sprocket head alignment sinceyou will be working from the other side of the engine while lining up the marks, since the cam drive is opposite that of the KLR and KLX650.

Based on your pictures they use the same sprockets on intake and exhaust, but use different marks labeled for which ever cam the sprocket is on. Be sure to pay attention to that marking. Get a look at a manual before you go any further to make sure how to do the work. Without a manual I can not precisely say the above method is right, but I'm thinking it is based on the pictures. If you have the crank at the T mark the cams look out of position, but again I do not know without actually looking at a shop manual to be sure it is supposed to be at the T mark and both cam lobe sets off the valves (valves closed, compression stroke) or not. Don't play around, get a look at a manual or if someone else here can confirm what I am saying, otherwise you're taking a risk. Maybe consider sending a PM to TNC. I believe he knows for sure. Others here do too, but I don't know them.

Last edited by klx678; 09-19-2010 at 06:02 AM.

#3

I don't know how the 250 is set up, but on the 650 there are two lines marked opposite each other on each cam sprocket. With the engine rotated to the top dead center (TDC) mark on the stator flywheel (marks are seen through the top smaller hole on the stator side cover) at the T mark, shown a bit closer in the little round inset picture:

these two lines on the cam sprockets are lined up in line with the top of the head like below.

This is an example from a KLR. The timing has nothing to do with the chain links, only how the cams line up at top dead center (TDC). That simple. If the KLX250 is similar to the KLR and KLX650 the setup will be the same, but in mirror image on the cam sprocket head alignment sinceyou will be working from the other side of the engine while lining up the marks, since the cam drive is opposite that of the KLR and KLX650.

Based on your pictures they use the same sprockets on intake and exhaust, but use different marks labeled for which ever cam the sprocket is on. Be sure to pay attention to that marking. Get a look at a manual before you go any further to make sure how to do the work. Without a manual I can not precisely say the above method is right, but I'm thinking it is based on the pictures. If you have the crank at the T mark the cams look out of position, but again I do not know without actually looking at a shop manual to be sure it is supposed to be at the T mark and both cam lobe sets off the valves (valves closed, compression stroke) or not. Don't play around, get a look at a manual or if someone else here can confirm what I am saying, otherwise you're taking a risk. Maybe consider sending a PM to TNC. I believe he knows for sure. Others here do too, but I don't know them.

these two lines on the cam sprockets are lined up in line with the top of the head like below.

This is an example from a KLR. The timing has nothing to do with the chain links, only how the cams line up at top dead center (TDC). That simple. If the KLX250 is similar to the KLR and KLX650 the setup will be the same, but in mirror image on the cam sprocket head alignment sinceyou will be working from the other side of the engine while lining up the marks, since the cam drive is opposite that of the KLR and KLX650.

Based on your pictures they use the same sprockets on intake and exhaust, but use different marks labeled for which ever cam the sprocket is on. Be sure to pay attention to that marking. Get a look at a manual before you go any further to make sure how to do the work. Without a manual I can not precisely say the above method is right, but I'm thinking it is based on the pictures. If you have the crank at the T mark the cams look out of position, but again I do not know without actually looking at a shop manual to be sure it is supposed to be at the T mark and both cam lobe sets off the valves (valves closed, compression stroke) or not. Don't play around, get a look at a manual or if someone else here can confirm what I am saying, otherwise you're taking a risk. Maybe consider sending a PM to TNC. I believe he knows for sure. Others here do too, but I don't know them.

thank you sir. i wish i would been more obersvent before i took it off. ya i was confused on if it woudl be at the end of a chain link or in the middle. all the diagrams i had showed at the end. but my cam lines up in middle the link unlike other diagrams shown. thank you once again for your help. and clearing up the issie if the cam has at end of link in the chain.

also here another picture of my final result. 32 links away from each other starting in middle of links look lot more straight with engine

http://img26.imageshack.us/img26/5566/img0230hi.jpg

Last edited by TweakInSleep; 09-19-2010 at 06:35 AM.

#4

I just read the stuff from the other thread. The other member backed up what I've said. Get the T mark lined up in the window, then make sure the lines on both sprockets line up with the head surface when there is tension on the exhaust side of the cam chain - like would be there if the tensioner was installed. The pin count should not matter, it should be an automatic occurance unless by some bizarre circumstance the chain has worn so far as to allow it to be off by an entire half link - which is virtually impossible.

There is no way the cams could move so as to be more or less than the 32 pins nor could the chain wear far enough in a 32 pin span to have it off that far. The steel doesn't "stretch", the pins wear within the link, causing the chain to elongate. To gain a half link in length would be such a huge amount of pin wear the chain would never be able to have enough slack taken out for the engine to run with the tensioner travel they have.

I am glad to have been some help. If you are having problems with the stock tensioner feel free to PM me, I am in the process of making the manual tensioners. At his original request, TNC and I have been working with the prototype I designed and made for him. We now have debugged the set up and it is ready to go. I will have them probably late next week. Price will be about 50% LESS than the OEM tensioner and will last the life of the bike. If you are mechanical enough to deal with valve adjustments and cam timing, you would have little if any problem with a manual tensioner.

There is no way the cams could move so as to be more or less than the 32 pins nor could the chain wear far enough in a 32 pin span to have it off that far. The steel doesn't "stretch", the pins wear within the link, causing the chain to elongate. To gain a half link in length would be such a huge amount of pin wear the chain would never be able to have enough slack taken out for the engine to run with the tensioner travel they have.

I am glad to have been some help. If you are having problems with the stock tensioner feel free to PM me, I am in the process of making the manual tensioners. At his original request, TNC and I have been working with the prototype I designed and made for him. We now have debugged the set up and it is ready to go. I will have them probably late next week. Price will be about 50% LESS than the OEM tensioner and will last the life of the bike. If you are mechanical enough to deal with valve adjustments and cam timing, you would have little if any problem with a manual tensioner.

Last edited by klx678; 09-19-2010 at 06:21 AM.

#5

I just read the stuff from the other thread. The other member backed up what I've said. Get the T mark lined up in the window, then make sure the lines on both sprockets line up with the head surface when there is tension on the exhaust side of the cam chain - like would be there if the tensioner was installed. The pin count should not matter, it should be an automatic occurance unless by some bizarre circumstance the chain has worn so far as to allow it to be off by an entire half link - which is virtually impossible.

There is no way the cams could move so as to be more or less than the 32 pins nor could the chain wear far enough in a 32 pin span to have it off that far. The steel doesn't "stretch", the pins wear within the link, causing the chain to elongate. To gain a half link in length would be such a huge amount of pin wear the chain would never be able to have enough slack taken out for the engine to run with the tensioner travel they have.

I am glad to have been some help. If you are having problems with the stock tensioner feel free to PM me, I am in the process of making the manual tensioners. At his original request, TNC and I have been working with the prototype I designed and made for him. We now have debugged the set up and it is ready to go. I will have them probably late next week. Price will be about 50% LESS than the OEM tensioner and will last the life of the bike. If you are mechanical enough to deal with valve adjustments and cam timing, you would have little if any problem with a manual tensioner.

There is no way the cams could move so as to be more or less than the 32 pins nor could the chain wear far enough in a 32 pin span to have it off that far. The steel doesn't "stretch", the pins wear within the link, causing the chain to elongate. To gain a half link in length would be such a huge amount of pin wear the chain would never be able to have enough slack taken out for the engine to run with the tensioner travel they have.

I am glad to have been some help. If you are having problems with the stock tensioner feel free to PM me, I am in the process of making the manual tensioners. At his original request, TNC and I have been working with the prototype I designed and made for him. We now have debugged the set up and it is ready to go. I will have them probably late next week. Price will be about 50% LESS than the OEM tensioner and will last the life of the bike. If you are mechanical enough to deal with valve adjustments and cam timing, you would have little if any problem with a manual tensioner.

#6

As long as the number of pins showing is correct, you should be fine. Always always turn the engine over at least four revolutions with a socket wrench on the flywheel before starting it with the starter. If you feel any binding when turning it over with the wrench stop and see whats wrong. You can destroy things if the timing is off and you simply hit the starter button.

good luck .

If you PM me your email I will email you the KLX 300 manual which is the base manual for the KLX250s. It has the info you need. You email has to handle about a 20mb file.

Dan

Last edited by dan888; 09-19-2010 at 02:22 PM.

#8

Tweak, if I'm understanding you correctly, that link pin deal is not important. It's just how the chain was threaded onto the crank gear and the rest of the cam drive. The pins don't know or care whether it's mid-link or on the end/beginning of the link as long as the number of pins showing is correct.

#9

Tweak, if I'm understanding you correctly, that link pin deal is not important. It's just how the chain was threaded onto the crank gear and the rest of the cam drive. The pins don't know or care whether it's mid-link or on the end/beginning of the link as long as the number of pins showing is correct.

#10

Tweak, if I'm understanding you correctly, that link pin deal is not important. It's just how the chain was threaded onto the crank gear and the rest of the cam drive. The pins don't know or care whether it's mid-link or on the end/beginning of the link as long as the number of pins showing is correct.

Want to pop your motor.....go for it.

Sayin.

Last edited by Finger Mullet; 09-19-2010 at 08:05 PM.