KLX250 EFI intermittent power loss, hard starting

#11

Started working on the bike this Monday, doing a big maintenance job, as well as hunting for that power loss problem.

I've found a mention on Thumper Talk that Kawasaki has some recalls regarding wiring harness on some particular years of KLX250, specifically the poster had wire chafing problem in the bundle of wires coming to the ECU connector. He had a similar power loss problem which was resolved after his dealer replaced his whole wiring harness according to that recall. The new harness he got has a longer plastic sleeve protecting the ECU connector wiring.

Derestrict klx250 2009 EFI for FREE - Page 5 - KLX/KLR 125/140/250/300 - ThumperTalk

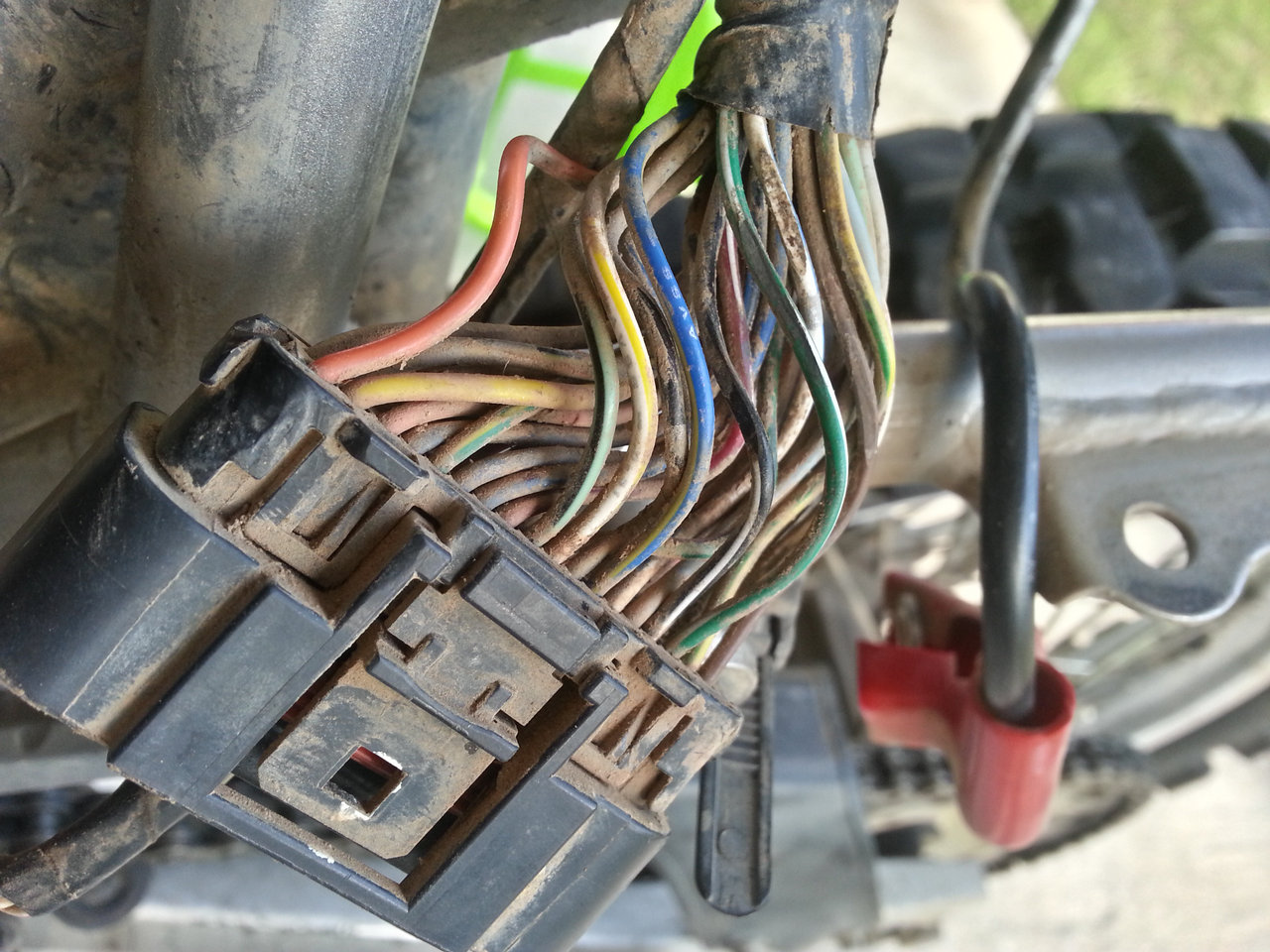

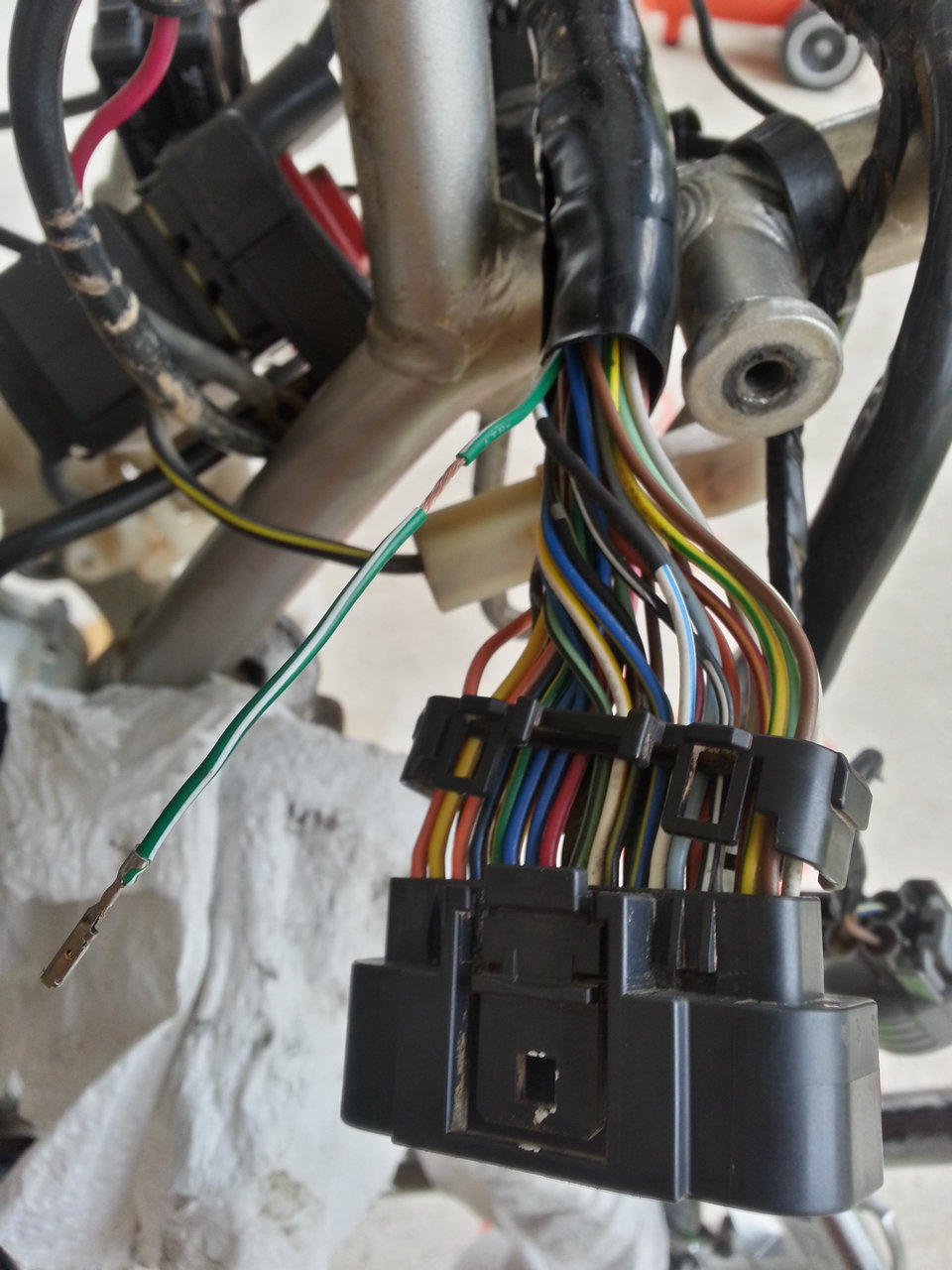

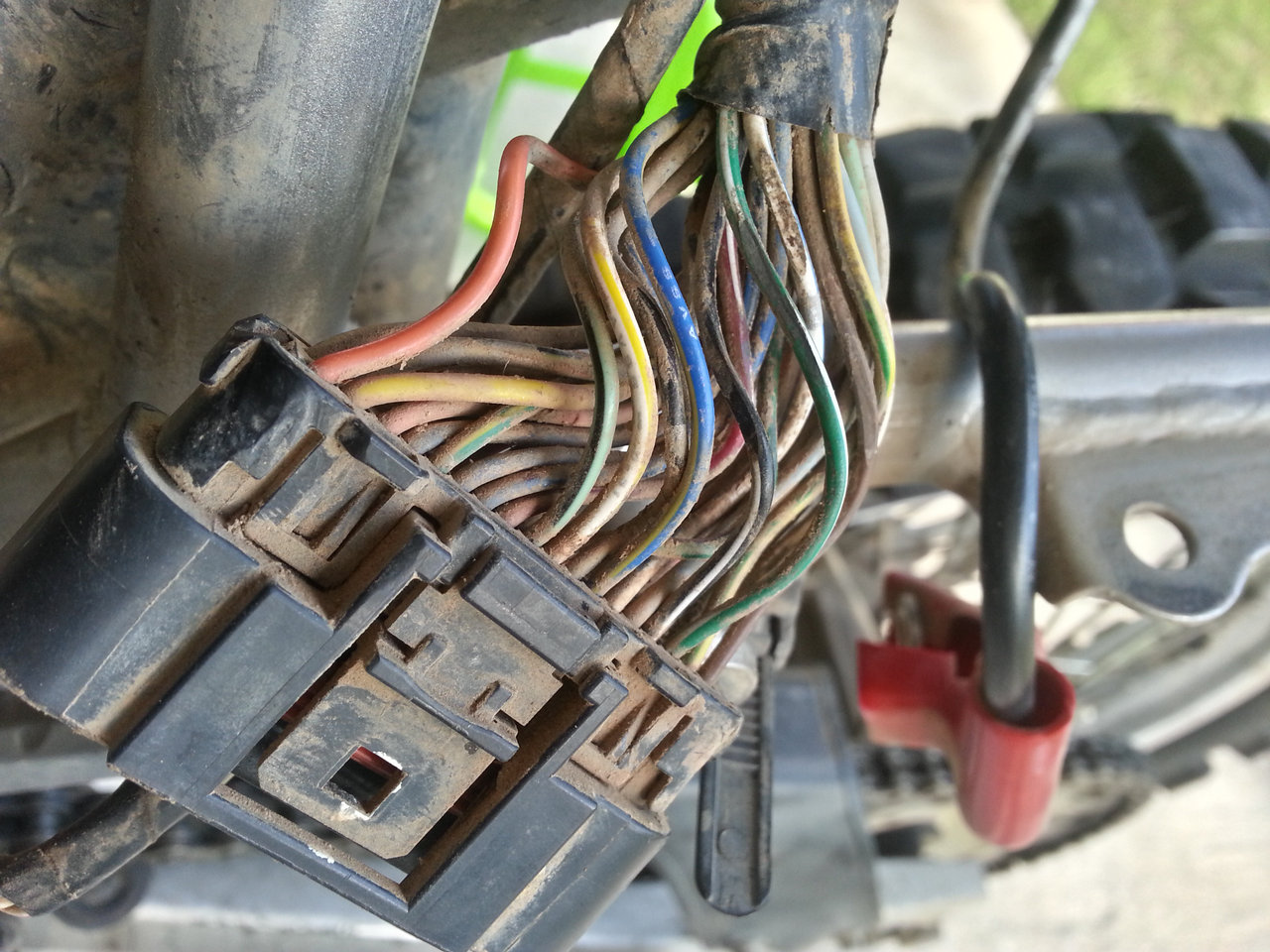

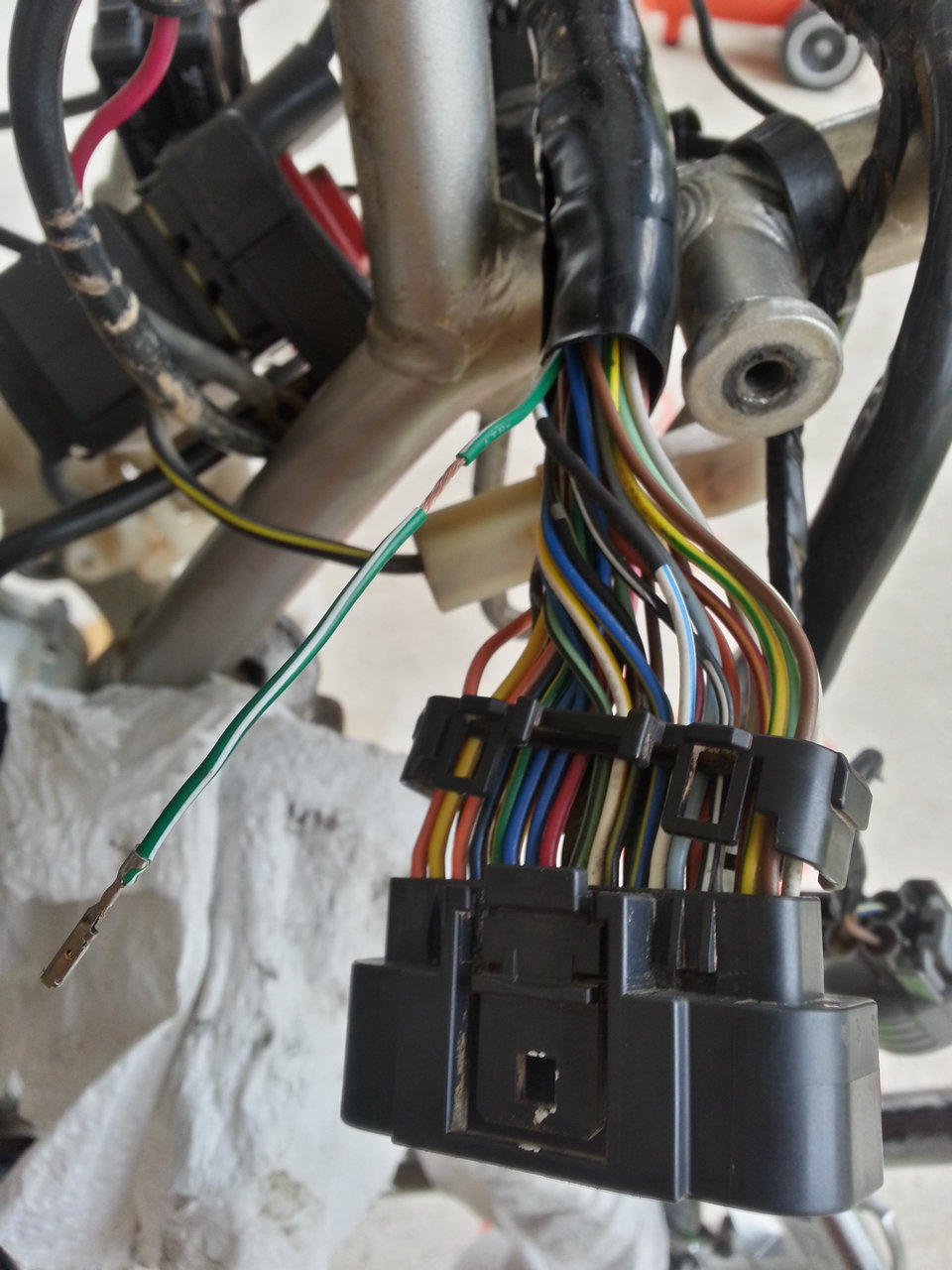

I checked my ECU connector wire bundle and there's no plastic sleeve, meaning I have one of these earlier harnesses (my bike is 2008 or 2009, I'm still not sure). The whole bundle of wires makes a rather sharp bend and is pushed against the subframe tube. Upon closer inspection at least a couple of wires look damaged, including one of the wires going to inlet air pressure sensor, and another one going to the crankshaft position sensor. I'm not sure what would happen if ECU doesn't get proper pressure sensor signal - engine stop or just imperfect fueling, but crankshaft position sensor wire intermittent contact would definitely mean complete engine stop. That makes sense, given that before the bike gave me the FI error code 21 which is the crankshaft sensor. Sounds like at least some of these stops were caused by this wire chafing.

I am gonna inspect that wire bundle more closely to see if there are any more su****ious wires. Since I live in countryside Thailand (4 hours drive to Bangkok), I'm thinking whether or not should I try to call Kawasaki dealer in Bangkok to check about this recall, or should I just repair (replace) these broken wires myself (I'm reasonably good with electrics jobs like this one).

I would advise to everybody to check their wiring near the ECU connector, and if the wires are not wrapped with electrical tape or a plastic sheath almost up to the connector itself, do it to prevent that kind of chafing.

I am still gonna check all the other suggestions I got here in this thread, thanks guys.

I've found a mention on Thumper Talk that Kawasaki has some recalls regarding wiring harness on some particular years of KLX250, specifically the poster had wire chafing problem in the bundle of wires coming to the ECU connector. He had a similar power loss problem which was resolved after his dealer replaced his whole wiring harness according to that recall. The new harness he got has a longer plastic sleeve protecting the ECU connector wiring.

Derestrict klx250 2009 EFI for FREE - Page 5 - KLX/KLR 125/140/250/300 - ThumperTalk

I checked my ECU connector wire bundle and there's no plastic sleeve, meaning I have one of these earlier harnesses (my bike is 2008 or 2009, I'm still not sure). The whole bundle of wires makes a rather sharp bend and is pushed against the subframe tube. Upon closer inspection at least a couple of wires look damaged, including one of the wires going to inlet air pressure sensor, and another one going to the crankshaft position sensor. I'm not sure what would happen if ECU doesn't get proper pressure sensor signal - engine stop or just imperfect fueling, but crankshaft position sensor wire intermittent contact would definitely mean complete engine stop. That makes sense, given that before the bike gave me the FI error code 21 which is the crankshaft sensor. Sounds like at least some of these stops were caused by this wire chafing.

I am gonna inspect that wire bundle more closely to see if there are any more su****ious wires. Since I live in countryside Thailand (4 hours drive to Bangkok), I'm thinking whether or not should I try to call Kawasaki dealer in Bangkok to check about this recall, or should I just repair (replace) these broken wires myself (I'm reasonably good with electrics jobs like this one).

I would advise to everybody to check their wiring near the ECU connector, and if the wires are not wrapped with electrical tape or a plastic sheath almost up to the connector itself, do it to prevent that kind of chafing.

I am still gonna check all the other suggestions I got here in this thread, thanks guys.

#13

I have finished checking all of the electrics. Ended up finding a whole bunch of wear&tear problems in different places, which made me quite surprised.

Besides the ECU connector, I've found some wire chafing in the wires going to the starter circuit relay and the lamp/ignition fuse holder. On these leads, the insulating tape was completely worn through, insulation on the wires was completely worn through, and some (almost half) of the copper conductors were broken off already. Soldered new wires, put these leads in strong sheaths, and taped over with electrical tape (OEM is just electrical tape). Ended up re-wrapping and reinforcing quite a bunch of the electrics.

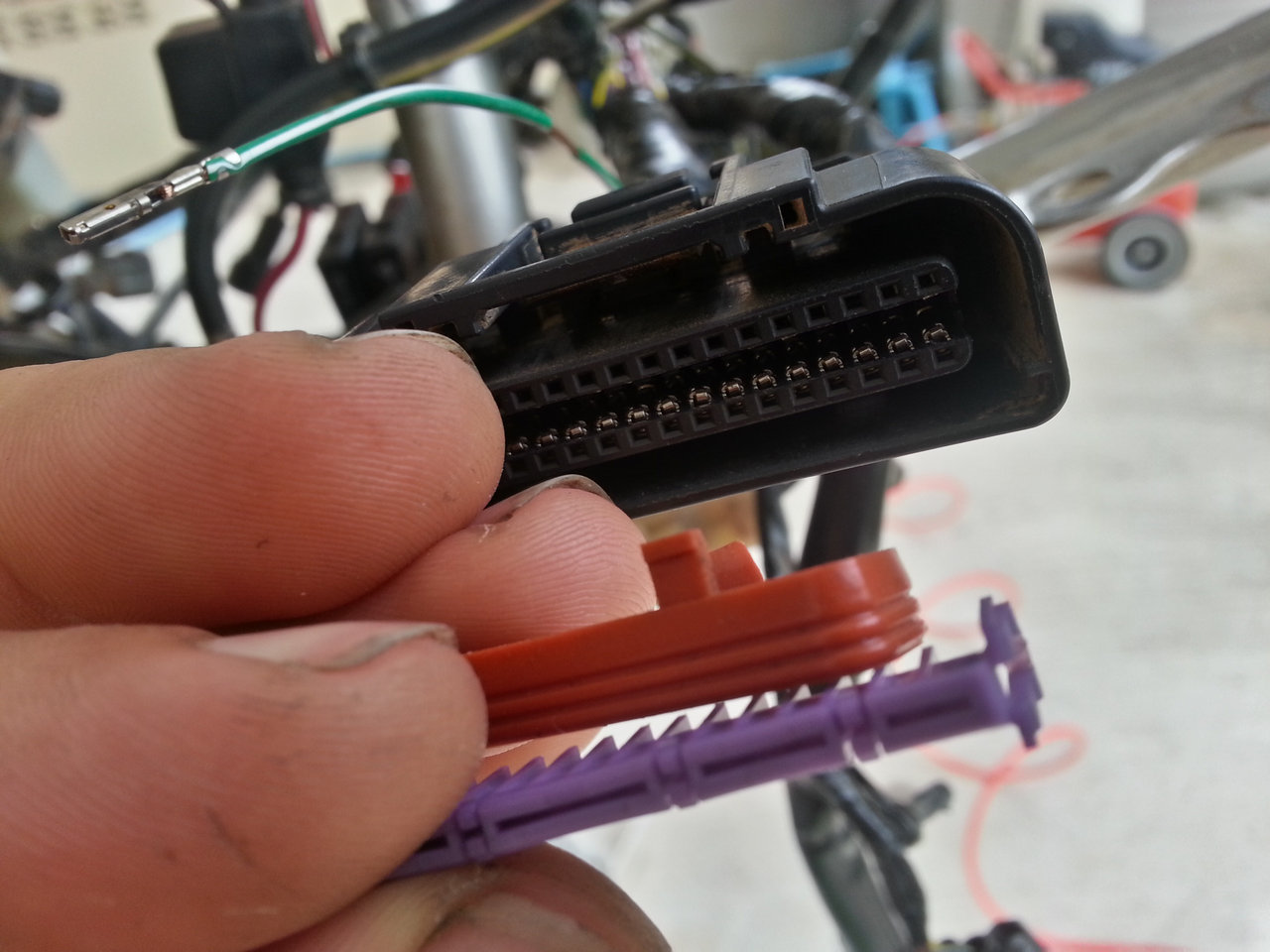

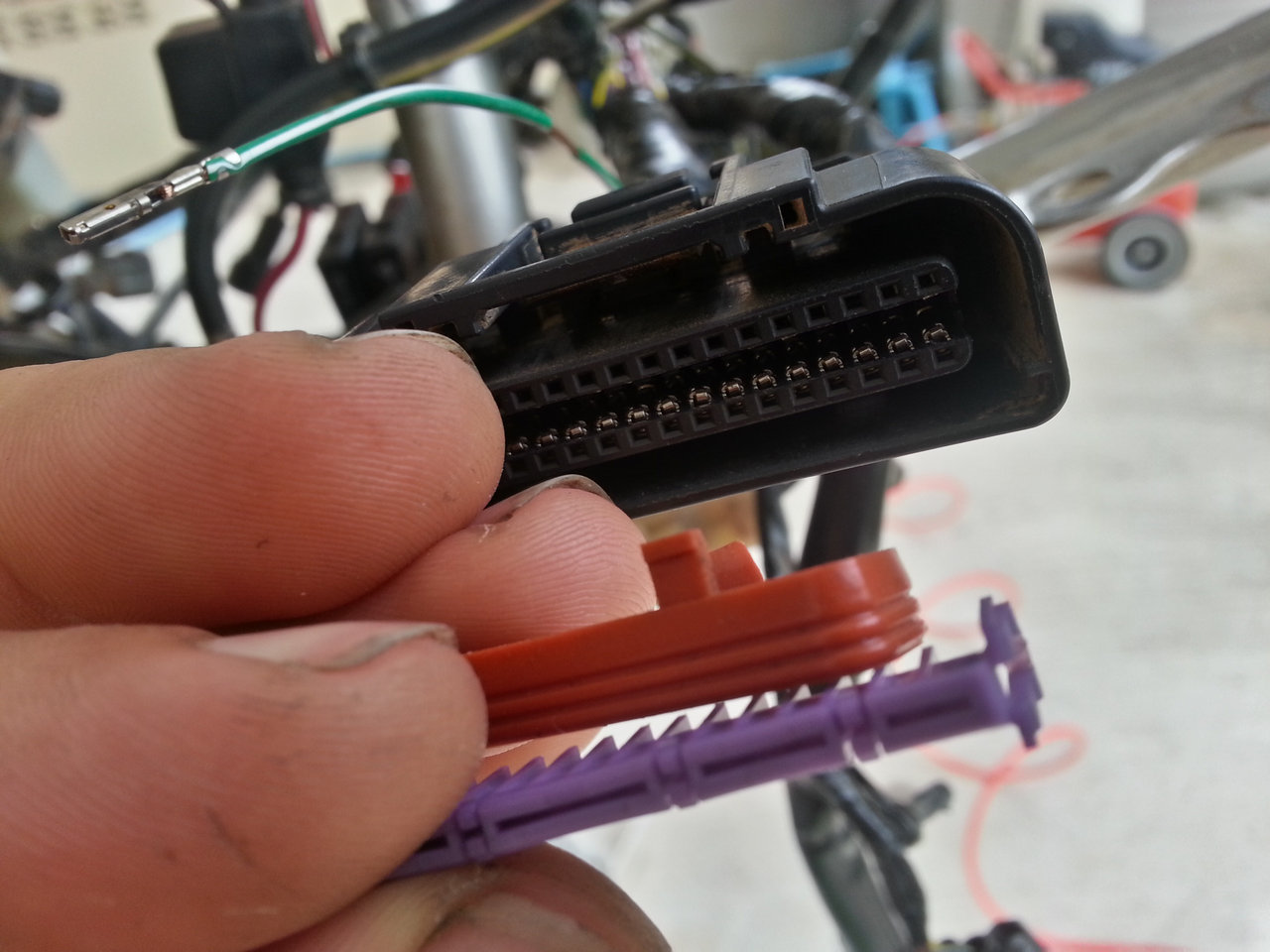

On the R/R to battery 3-pole connector one of the terminal retainers (plastic tab inside the connector housing) was broken off and the terminal was not held securely in the connector, also that terminal looked somewhat corroded. Luckily I had a nice waterproof MetriPack 280 3-pole connector on hand, which I promptly used as a replacement for the OEM connector.

Minor issue - the sheath covering the taillight/rear turn signals lead was worn through a bit in an area that rubs against the upper black plastic fender/cover, which has a really sharp rough edge there, wrapped the lead with tape and smoothed out that sharp edge.

Additionally, and it really surprised me, the engine kill switch on the handlebar was making intermittent connection, opened it and it was just dirty, nothing looked damaged, cleaned with contact cleaner and polished the contacts up with some 600 grit sandpaper, reassembled with a little dielectric grease.

So in total a whole bunch of electric-related problems, many of them about wire chafing, I wonder what could cause that in several different places. I guess that OEM wire harness is not that great in some spots.

Still a bunch of work to do (putting in new piston and replacing valve seals), and waiting for a new swingarm, since I found out the old one was damaged some time in the past when I had a mechanic replace my swingarm bearings.

Besides the ECU connector, I've found some wire chafing in the wires going to the starter circuit relay and the lamp/ignition fuse holder. On these leads, the insulating tape was completely worn through, insulation on the wires was completely worn through, and some (almost half) of the copper conductors were broken off already. Soldered new wires, put these leads in strong sheaths, and taped over with electrical tape (OEM is just electrical tape). Ended up re-wrapping and reinforcing quite a bunch of the electrics.

On the R/R to battery 3-pole connector one of the terminal retainers (plastic tab inside the connector housing) was broken off and the terminal was not held securely in the connector, also that terminal looked somewhat corroded. Luckily I had a nice waterproof MetriPack 280 3-pole connector on hand, which I promptly used as a replacement for the OEM connector.

Minor issue - the sheath covering the taillight/rear turn signals lead was worn through a bit in an area that rubs against the upper black plastic fender/cover, which has a really sharp rough edge there, wrapped the lead with tape and smoothed out that sharp edge.

Additionally, and it really surprised me, the engine kill switch on the handlebar was making intermittent connection, opened it and it was just dirty, nothing looked damaged, cleaned with contact cleaner and polished the contacts up with some 600 grit sandpaper, reassembled with a little dielectric grease.

So in total a whole bunch of electric-related problems, many of them about wire chafing, I wonder what could cause that in several different places. I guess that OEM wire harness is not that great in some spots.

Still a bunch of work to do (putting in new piston and replacing valve seals), and waiting for a new swingarm, since I found out the old one was damaged some time in the past when I had a mechanic replace my swingarm bearings.

#16

Got the bike sorted out. Found a bunch of problems.

1) I found some info that the ECU connector lead is prone to chafing on the 2009 model bikes, a forum posting even mention there was a recall about that, and the newer part number for the wiring harness has that problem fixed by wrapping the ECU connector lead in electrical tape almost until the connector itself. On mine, a couple of wires had their insulation chafed through to the bare copper, some of the copper strands broken and the rest had minor corrosion. One of the wires was from the crankshaft position sensor - if the ECU doesn't get proper signal from this sensor, I doubt the engine can work at all. I had the FI indicator light showing "error 21" which is the crankshaft position sensor a couple of times, but not always, when the bike failed to start. Couple more wires had insulation partially chafed through, but copper still not visible. Fixed by soldering and heat-shrink tubing (disassembled the ECU connector and release the affected wires' terminals to get access). I verified each and every circuit continuity on the bike with a multimeter. Took a while with the wiring diagram, but felt pretty satisfying.

I also found several wires chafed on the leads coming to the fuse holders and started circuit relay. Don't know what exactly did that damage because these leads stay between the airbox and the black plastic fender part, no sharp edges there, just rubbing against the plastic for many thousands of kilometers I guess. Again, insulation was worn through and half of the copper strands were broken, no corrosion though. Fixed by soldering and heat-shrink tubing.

After all the wiring was fixed, I cut some high-temp PVC sheathing lengthwise and cover the leads with that, then taped over with nice 3M electrical tape. The ECU connector lead I wrapped with a more flexible but really thick and tough 3M rubber splicing tape, then overwrapped with the electrical tape.

Pics of somewhat damaged ECU connector wiring:

2) I didn't expect any problems there, even I was almost too lazy to check with a multimeter, but luckily I was too **** about that, so I did check and to my surprise the Engine Run switch was intermittently not working in the RUN position. Push on the button a bit more and there was a connection, let go and sometimes the multimeter would keep beeping, sometimes it would stop. I always figured these switches are well sealed and never fail. Got the switch housing open, disassembled the switch, it looked a bit dirty but not that bad. Cleaned everything, touched up the contact points with 400 grit sandpaper, put just a thin film of dielectric grease on everything and reassembled, problem solved. Actually I figure it might have been THE main reason why my bike quit running or wouldn't start intermittently. I'm in the habit of always using the Engine Run switch to kill my engine when I stop riding, just to get this good habit for situations when I need it (when going down) - might be that contributed to developing this problem.

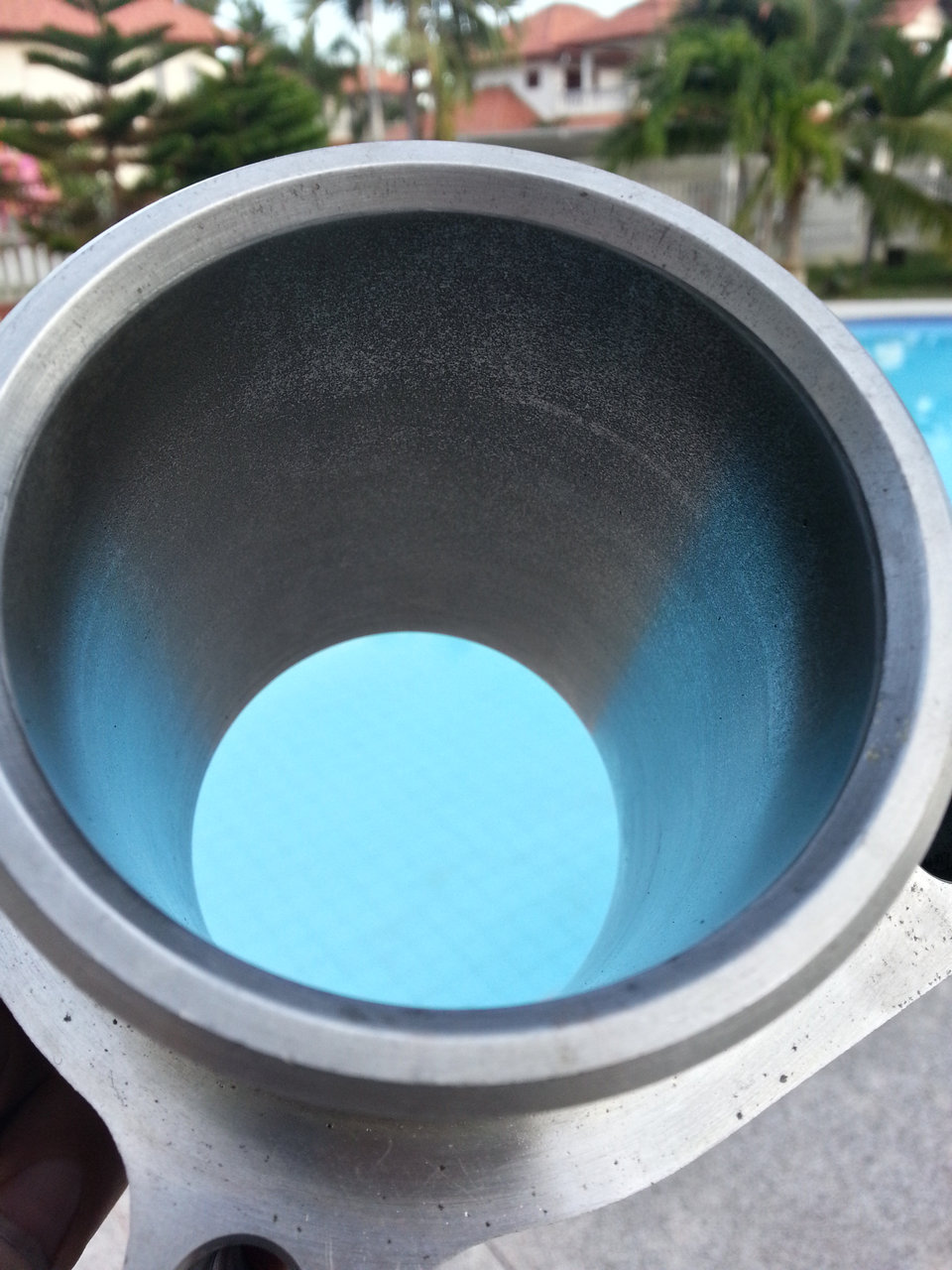

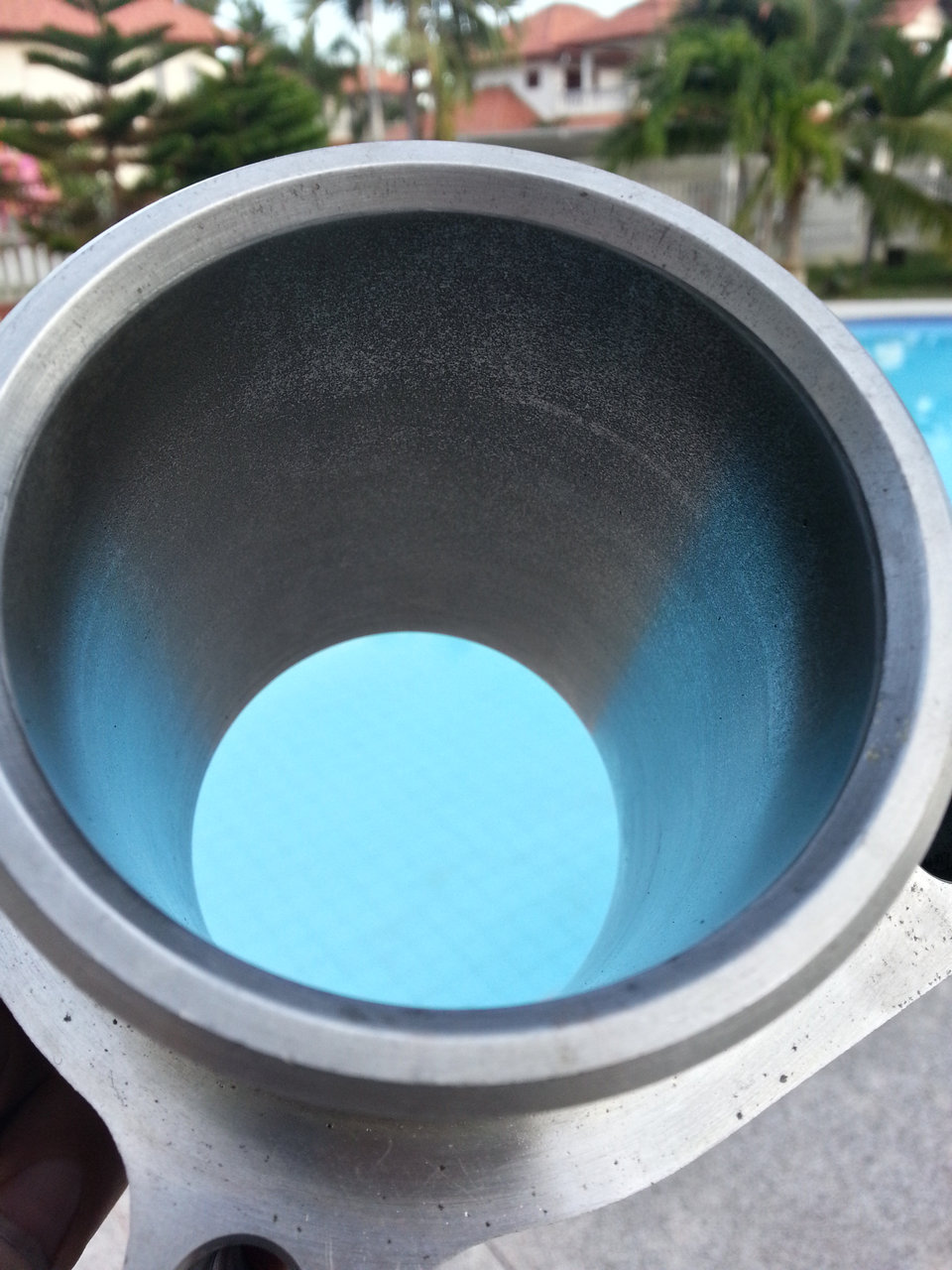

3) The piston rings were worn, piston had a lot of deposits, valves had a lot of deposits, the exhaust valves had deep pitting and their seats also had minor pitting. The bike definitely had low compression and the cam chain was noisy.

I got a new piston, rings and pin a while ago, I got a local mechanic deglaze&hone the cylinder for me, actually with this cylinder and the new piston and rings the clearances and ring end gaps are pretty loose, still within service limit but not that good. However having no spare cylinder - and a new one is not on the budget for now - I decided to install things as is and hope it will last long enough until I get another cylinder. New exhaust valves, cleaned the intake valves, my wife did the valve lapping, new valve stem seals, cam chain and tensioners, put in a krieger manual cam chain tensioner as well. Did the Marcelino cam timing mod, disabled ACR with a bent piece of thick steel wire replacing the ACR spring.

My swingarm bearings were shot, got the old ones out - they almost fell out with one hit with a hammer, found out the bearing holes are damaged, especially the outside part where the seals sit. Tried new seals in there - I could see a gap of at least 1mm. Since a new swingarm is pretty cheap here in Thailand, and the old one also had some deep (>2mm) groove cut with a completely worn-out sidestand (previous owner legacy), I decided to get a new one, put in new bearings, sleeves and seals. Also a pair of shock arm bearings were rusted (actually I found that out earlier, but having no replacement bearings put a bunch of grease in there and rode it like that for a month). Replaced all the shock arm bearings, sleeves and seals.

I'm 80kg, often carry my wife as a passenger, and a bunch of travel gear or grocery shopping, the stock spring is too soft, but I cranked up the preload to 121mm (measured according to the manual), close to the manual specified limit of 123mm, that's 13.5mm more preload than standard (107.5mm), bike feels much better now and doesn't sag under the weight of passenger&luggage. With just me on the bike, no gear/luggage, I have a rear rider sag of 58mm (25% of full travel), obviously more with riding gear etc. However, bike sag is basically zero - ideally I should get a harder spring. I don't know why I never bothered to adjust preload before, it's not difficult and is useful adjustment. I should get a shock wrench though, a punch and a hammer took a while to turn the adjuster ring 9 full turns.

Anyway, 100 days since I started the rebuild, I fired up the bike, it came to life so quickly. Gave it a hard break-in, changed the oil after 30km, did another hard day of riding today (going grocery shopping). Feels great to ride again. The bike's sound somewhat different than before as well.

1) I found some info that the ECU connector lead is prone to chafing on the 2009 model bikes, a forum posting even mention there was a recall about that, and the newer part number for the wiring harness has that problem fixed by wrapping the ECU connector lead in electrical tape almost until the connector itself. On mine, a couple of wires had their insulation chafed through to the bare copper, some of the copper strands broken and the rest had minor corrosion. One of the wires was from the crankshaft position sensor - if the ECU doesn't get proper signal from this sensor, I doubt the engine can work at all. I had the FI indicator light showing "error 21" which is the crankshaft position sensor a couple of times, but not always, when the bike failed to start. Couple more wires had insulation partially chafed through, but copper still not visible. Fixed by soldering and heat-shrink tubing (disassembled the ECU connector and release the affected wires' terminals to get access). I verified each and every circuit continuity on the bike with a multimeter. Took a while with the wiring diagram, but felt pretty satisfying.

I also found several wires chafed on the leads coming to the fuse holders and started circuit relay. Don't know what exactly did that damage because these leads stay between the airbox and the black plastic fender part, no sharp edges there, just rubbing against the plastic for many thousands of kilometers I guess. Again, insulation was worn through and half of the copper strands were broken, no corrosion though. Fixed by soldering and heat-shrink tubing.

After all the wiring was fixed, I cut some high-temp PVC sheathing lengthwise and cover the leads with that, then taped over with nice 3M electrical tape. The ECU connector lead I wrapped with a more flexible but really thick and tough 3M rubber splicing tape, then overwrapped with the electrical tape.

Pics of somewhat damaged ECU connector wiring:

2) I didn't expect any problems there, even I was almost too lazy to check with a multimeter, but luckily I was too **** about that, so I did check and to my surprise the Engine Run switch was intermittently not working in the RUN position. Push on the button a bit more and there was a connection, let go and sometimes the multimeter would keep beeping, sometimes it would stop. I always figured these switches are well sealed and never fail. Got the switch housing open, disassembled the switch, it looked a bit dirty but not that bad. Cleaned everything, touched up the contact points with 400 grit sandpaper, put just a thin film of dielectric grease on everything and reassembled, problem solved. Actually I figure it might have been THE main reason why my bike quit running or wouldn't start intermittently. I'm in the habit of always using the Engine Run switch to kill my engine when I stop riding, just to get this good habit for situations when I need it (when going down) - might be that contributed to developing this problem.

3) The piston rings were worn, piston had a lot of deposits, valves had a lot of deposits, the exhaust valves had deep pitting and their seats also had minor pitting. The bike definitely had low compression and the cam chain was noisy.

I got a new piston, rings and pin a while ago, I got a local mechanic deglaze&hone the cylinder for me, actually with this cylinder and the new piston and rings the clearances and ring end gaps are pretty loose, still within service limit but not that good. However having no spare cylinder - and a new one is not on the budget for now - I decided to install things as is and hope it will last long enough until I get another cylinder. New exhaust valves, cleaned the intake valves, my wife did the valve lapping, new valve stem seals, cam chain and tensioners, put in a krieger manual cam chain tensioner as well. Did the Marcelino cam timing mod, disabled ACR with a bent piece of thick steel wire replacing the ACR spring.

My swingarm bearings were shot, got the old ones out - they almost fell out with one hit with a hammer, found out the bearing holes are damaged, especially the outside part where the seals sit. Tried new seals in there - I could see a gap of at least 1mm. Since a new swingarm is pretty cheap here in Thailand, and the old one also had some deep (>2mm) groove cut with a completely worn-out sidestand (previous owner legacy), I decided to get a new one, put in new bearings, sleeves and seals. Also a pair of shock arm bearings were rusted (actually I found that out earlier, but having no replacement bearings put a bunch of grease in there and rode it like that for a month). Replaced all the shock arm bearings, sleeves and seals.

I'm 80kg, often carry my wife as a passenger, and a bunch of travel gear or grocery shopping, the stock spring is too soft, but I cranked up the preload to 121mm (measured according to the manual), close to the manual specified limit of 123mm, that's 13.5mm more preload than standard (107.5mm), bike feels much better now and doesn't sag under the weight of passenger&luggage. With just me on the bike, no gear/luggage, I have a rear rider sag of 58mm (25% of full travel), obviously more with riding gear etc. However, bike sag is basically zero - ideally I should get a harder spring. I don't know why I never bothered to adjust preload before, it's not difficult and is useful adjustment. I should get a shock wrench though, a punch and a hammer took a while to turn the adjuster ring 9 full turns.

Anyway, 100 days since I started the rebuild, I fired up the bike, it came to life so quickly. Gave it a hard break-in, changed the oil after 30km, did another hard day of riding today (going grocery shopping). Feels great to ride again. The bike's sound somewhat different than before as well.

Last edited by Gene Pavlovsky; 12-05-2014 at 07:55 PM.

#18

Nice collar on the kitty kat too

#20

Yep, it's so lovely to be able to ride again! I didn't have my bike since February - was too busy to fix it. I hope I'm never without a bike again!

Wife kept complaining I don't give her enough jobs on the motorbike. I figured a good show of trust (she's no mechanic) is to show her how to lap valves

The guy with his hand in a cast is my neighbor, and the scenery in the pic is his wakeboard cable park / kiteboard school (called Kite Cable), the cat is the big boss around there. He's an avid DH rider, broke his hand recently on a botched up jump. He can't wait to get riding again - plans to do so in two weeks. He's way crazy dude

Wife kept complaining I don't give her enough jobs on the motorbike. I figured a good show of trust (she's no mechanic) is to show her how to lap valves

The guy with his hand in a cast is my neighbor, and the scenery in the pic is his wakeboard cable park / kiteboard school (called Kite Cable), the cat is the big boss around there. He's an avid DH rider, broke his hand recently on a botched up jump. He can't wait to get riding again - plans to do so in two weeks. He's way crazy dude