HOW TO: Fork oil change

#1

Just last weekend I went to a suspension servicing demo where I learned a ton. The two main things I learned were that firstly you are supposed to service your suspension regularly, and the second is WHY you need to service it. There does not seem to be any authoritative guidance on how frequently to do it, with opinions varying from every 6 months to every 12 months. But it goes without saying that the harder your suspension works the more frequently you should service it, and even if your suspension doesn't work hard you should service it at least annually. The demo I saw was on a bike rear shock that had been serviced just 3 months ago and had only done 2 track days, and in spite of that the oil still had dirt in it. I was staggered!

Now, I bought my bike in about April 2010, so just over 3 years ago, and the only suspension work it's had is new springs for my fat frame. So it was WELL overdue an oil service! After getting a quote on how much the suspension tuner that did an awesome job on my Husky would charge to do the servicing, I was put off though. I am currently unemployed and so cannot afford over $500 for the service and new seals. So I took a look at the fork service instructions on Planet KLX (CHANGE YOUR FORK OIL) and in the service manual (section 13-10 to 13-12) and decided I could do the service - excluding the seals - myself without a workshop.

I figured I am not the only one that has neglected my suspension so much, and that the KLX community would appreciate a bit of a novices guide to changing the oil themselves. I did do a search but didn't find much, and I prefer watching a video to get a better idea of how easy/difficult it is anyway. The video's I found on YouTube were mainly for twin-chamber or closed-cartridge forks, and invariably the guides were more focused on seal changes than just oil changes. There is probably a good reason for that, as it is advisable that you do your seals and bushes at the same time. It doesn't seem that difficult, and it only really needs a couple of extra tools - mainly a seal driver - and of course the seals. But I'm broke and doing the cheap-and-nasty fork service rather than doing it "properly".

This guide is NOT a complete guide on how to do the job. I am NOT a qualified or experienced suspension tuner or even a mechanic. I am a weekend hack that is trying to do the right thing whist saving money. So if you plan on doing this job yourself, please do your own research and don't rely solely on this little guide. I highly recommend you get a proper tuner that knows what they are doing to do the job if you can afford it.

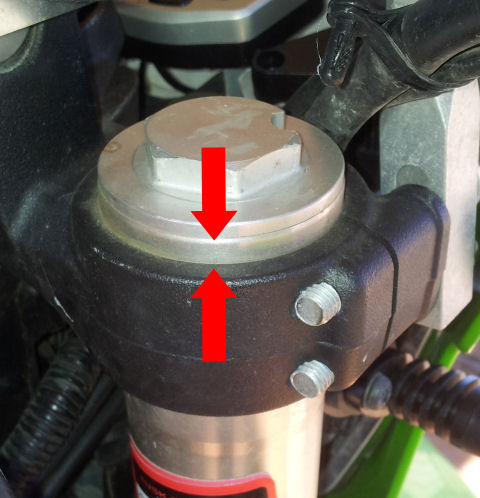

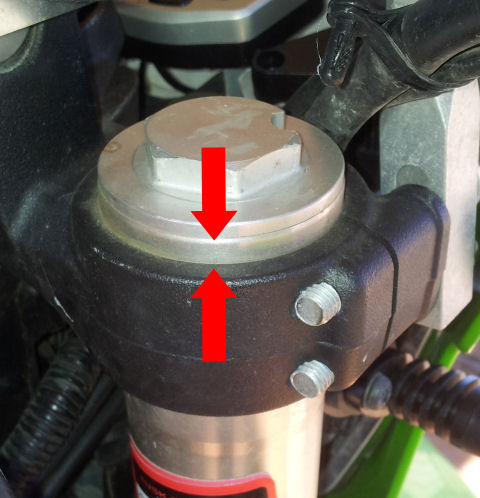

Now, before you start, I would advise you take photo's of the way that cables are routed around the forks (especially at the bottom of the forks) measure the distance your forks stick out above the top clamp, and take note of your clicker settings (they shouldn't change, but best be safe than sorry). In the images below you can see the way my brake line and speedo cable route around the fork, and you can see that the forks stick out a few millimeters from the top clamp. Now, when I put the forks back in I intend to make them flush with the top mount as I mainly use the bike on paved roads now so need more stability at higher speeds than tight turning handling. You can research this a bit more if you like, it has to do with the angle of "rake" I believe. I don't honestly know how much of a difference it will make, but I thought I had better mention it for your benefit.

Remove the front wheel and the fork guards so that you will be able to remove the forks. This is the point where you can read the service manual guide on what to do, but you can get an idea of what to do from my video (about 22 minutes - and it's available in HD):

As you can see from the first picture below, the fork oil was FILTHY! Not only that, but it was syrup-like rather than the nice flowing oil that it should be, and when rubbing it between the ingers it had a very fine gritty feeling. I shudder to think how horribly is would have flowed through the valve piston ports and past the shims, and what damage the fine grit would have been doing to them. Given it was so dirty I decided to flush the forks out with fresh oil (DON'T use kerosine like I originally did as any residual kero in the forks that you do not drain out properly will break down the fork oil over time) too in order to try get rid of whatever muck was in the forks. Even after I flushed the fork out the fluid I drained out was very dirty (as you can see in the second picture below).

If you do want to do the service yourself you will need the following:

Working (roughly) from the back row left hand side to the front right:

So the process is roughly:

1) Remove fork

2) Open fork cap

3) Remove fork cap and spring

4) Drain old oil out

5) Flush fork with Kerosine

6) Install fresh oil and bleed air out

7) Install spring

8) Pull up fork rod and screw fork cap back onto rod

9) Screw fork cap back into outter fork tube

10) Install fork back into clamps

Hope this is helpful.

Now, I bought my bike in about April 2010, so just over 3 years ago, and the only suspension work it's had is new springs for my fat frame. So it was WELL overdue an oil service! After getting a quote on how much the suspension tuner that did an awesome job on my Husky would charge to do the servicing, I was put off though. I am currently unemployed and so cannot afford over $500 for the service and new seals. So I took a look at the fork service instructions on Planet KLX (CHANGE YOUR FORK OIL) and in the service manual (section 13-10 to 13-12) and decided I could do the service - excluding the seals - myself without a workshop.

I figured I am not the only one that has neglected my suspension so much, and that the KLX community would appreciate a bit of a novices guide to changing the oil themselves. I did do a search but didn't find much, and I prefer watching a video to get a better idea of how easy/difficult it is anyway. The video's I found on YouTube were mainly for twin-chamber or closed-cartridge forks, and invariably the guides were more focused on seal changes than just oil changes. There is probably a good reason for that, as it is advisable that you do your seals and bushes at the same time. It doesn't seem that difficult, and it only really needs a couple of extra tools - mainly a seal driver - and of course the seals. But I'm broke and doing the cheap-and-nasty fork service rather than doing it "properly".

This guide is NOT a complete guide on how to do the job. I am NOT a qualified or experienced suspension tuner or even a mechanic. I am a weekend hack that is trying to do the right thing whist saving money. So if you plan on doing this job yourself, please do your own research and don't rely solely on this little guide. I highly recommend you get a proper tuner that knows what they are doing to do the job if you can afford it.

Now, before you start, I would advise you take photo's of the way that cables are routed around the forks (especially at the bottom of the forks) measure the distance your forks stick out above the top clamp, and take note of your clicker settings (they shouldn't change, but best be safe than sorry). In the images below you can see the way my brake line and speedo cable route around the fork, and you can see that the forks stick out a few millimeters from the top clamp. Now, when I put the forks back in I intend to make them flush with the top mount as I mainly use the bike on paved roads now so need more stability at higher speeds than tight turning handling. You can research this a bit more if you like, it has to do with the angle of "rake" I believe. I don't honestly know how much of a difference it will make, but I thought I had better mention it for your benefit.

Remove the front wheel and the fork guards so that you will be able to remove the forks. This is the point where you can read the service manual guide on what to do, but you can get an idea of what to do from my video (about 22 minutes - and it's available in HD):

As you can see from the first picture below, the fork oil was FILTHY! Not only that, but it was syrup-like rather than the nice flowing oil that it should be, and when rubbing it between the ingers it had a very fine gritty feeling. I shudder to think how horribly is would have flowed through the valve piston ports and past the shims, and what damage the fine grit would have been doing to them. Given it was so dirty I decided to flush the forks out with fresh oil (DON'T use kerosine like I originally did as any residual kero in the forks that you do not drain out properly will break down the fork oil over time) too in order to try get rid of whatever muck was in the forks. Even after I flushed the fork out the fluid I drained out was very dirty (as you can see in the second picture below).

If you do want to do the service yourself you will need the following:

Working (roughly) from the back row left hand side to the front right:

- Contact cleaner - just for cleaning parts like the spring and fork cap. I would recommend contact cleaner rather than degreaser as it's easier on any rubber it might come in contact with (like the O-ring) and it evaporates away so it doesn't contaminate the fresh oil you put in the forks.

- Fresh fork oil - to flush the forks out and to obviously refill. Flushing is not manditory, but I thought it was a good idea. I used 5W oil as this is what I was told is the standard. I have since learned that the weight of the oil is not nearly as important as the viscosity. Check out this wiki for viscosity comparisons: Suspension Fluid - Pvdwiki The Belray I used is quite thin at 17 centiStrokes (cSt @ 40C). Do your research on what might suit you best.

- Fork Spring Holder - hold the spring down on the fork rod. I didn't really end up needing this though

- Fork Oil Level tool - this is basically a piece of straight tube and a syringe. You basically measure the height of the oil from the top of the fork (without the spring installed) and suck out any excess. I used some insulation tape to mark 100mm (4 inches) to suck out - Planet KLX recommend 95mm and the service manual recommends 101mm. You can read up on this, but basically the higher the fork oil height meaurement the more oil you suck out and the more air there is in the fork. More air means there is more "give" before the compressed air starts acting like a spring itself (like the new PSF forks that some of the AMA riders have been using. If you are too heavy for the springs you have in your forks, you can minimise your forks bottoming out by having less air in the forks (e.g. only pull out 90mm of oil) - but be warned, this will put extra pressure on your fork seals and you may end up blowing out your fork seals quicker if you do this. Again, do your research.

- String - this is a cheap trick to putt up the fork rod through the spring when you re-install it (see the video)

- Ruler to measure the fork oil height (not in picture, but you need one)

- 12mm T-bar spanner for the bolts on the fork clams to remove/reinstall the forks securely

- 30mm Fork Cap wrench to undo and tighten the fork cap

- 17mm spanner to hold the piston rod nut when removing the fork cap from the rod so you can take the spring off

You will obviously also need a container to drain the old fork oil and flushing kerosine into.

So the process is roughly:

1) Remove fork

2) Open fork cap

3) Remove fork cap and spring

4) Drain old oil out

5) Flush fork with Kerosine

6) Install fresh oil and bleed air out

7) Install spring

8) Pull up fork rod and screw fork cap back onto rod

9) Screw fork cap back into outter fork tube

10) Install fork back into clamps

Hope this is helpful.

Last edited by Arctra; 07-23-2013 at 11:44 PM.

#5

No. I got 2 x 1 litre bottles of oil and used about 1 1/3 bottles in the end. I would say get yourself about 1.5 litres to be safe.

#6

Just a cheap trick that i used on my bikes. If you dont have one of those syringe fork oil adjuster tools, just use a sprayer off of a window cleaner bottle or any other bottle with a pump spray, measure from the bottom of the cap that screws onto a bottle and then cut the tube at the correct length and there ya go just stick it into the fork tube and pump out the excess oil.

#7

After speaking to a Suspension tuner, flushing with Kerosene is a BAD idea as any residuals that you don't drain properly will break down the fork oil over time. So rather flush with fresh fork oil.

#8

Oh, and another thing I learned is that the weight of the fork oil you choose isn't nearly as important as the fluid viscosity. 5W Belray is 17 centiStrokes at 40C whereas 5W Motorex is about 22.6 cSt@40C - quite a difference in viscosity for the same weight rating. There is a good viscosity comparison table on this wiki that can help you: Suspension Fluid - Pvdwiki

The more viscous the fluid, the more resistance there will be as the fluid flows through the valve and past the shims - so effectively the more damping you'll have. If you choose a more viscous fluid, you may need to compensate by winding your compression/rebound damping clickers. Conversely, if you choose a lighter fluid, you may need to wind your clickers in to give you more damping to compensate for the freer flowing fluid.

The manual says to use Kayaba 01 (KHL 15-10) oil which has a viscosity of 15.6 cSt@40C according to the Wiki, so you can use that as a guide.

The more viscous the fluid, the more resistance there will be as the fluid flows through the valve and past the shims - so effectively the more damping you'll have. If you choose a more viscous fluid, you may need to compensate by winding your compression/rebound damping clickers. Conversely, if you choose a lighter fluid, you may need to wind your clickers in to give you more damping to compensate for the freer flowing fluid.

The manual says to use Kayaba 01 (KHL 15-10) oil which has a viscosity of 15.6 cSt@40C according to the Wiki, so you can use that as a guide.

#9

Thanks for the info and nice write up on the process. It came at the perfect time since I noticed I was leaking fluid out of one of the forks a couple of weeks back. Also I figure it's as good a time as any to upgrade to the racetech gold valves since I have to pull the forks apart to replace the seals.

I upgraded to moto-pro springs front and back last fall. What a difference that made! Hoping the gold valves will help prevent that dreaded compression spike I experienced this spring that sent me crashing hard to the ground.

According to the chart I picked an oil with similar viscosity as you have. I ended up with the Honda Pro HP 5wt. 17.00 on the chart. It is ok If I use Honda oil in my Kawi right? It is a red '09!

I upgraded to moto-pro springs front and back last fall. What a difference that made! Hoping the gold valves will help prevent that dreaded compression spike I experienced this spring that sent me crashing hard to the ground.

According to the chart I picked an oil with similar viscosity as you have. I ended up with the Honda Pro HP 5wt. 17.00 on the chart. It is ok If I use Honda oil in my Kawi right? It is a red '09!