Fuel/air mix strategy for TAT ride?

#11

Thanks for your good info. I guess I will have to get back into the carb and install some of these other jets I have laying around. I have done no long rides and don't want to damage the engine on a long haul. I have most DJ sizes from 136 to 150 and an untried 40 pilot, still have the 35 that has always been in there. So current is 35 pilot and 144 main with 2N if I remember correctly, will try 40 and 148 1N this week.

IIRC, you are a 351, stock header, Leo Vince slipon, CVK and lidless airbox.. If you have (or go with) a performance header, put in a DJ150 or DJ152 instead of a DJ148..

Last edited by Klxster; 10-29-2019 at 04:18 AM.

#12

#13

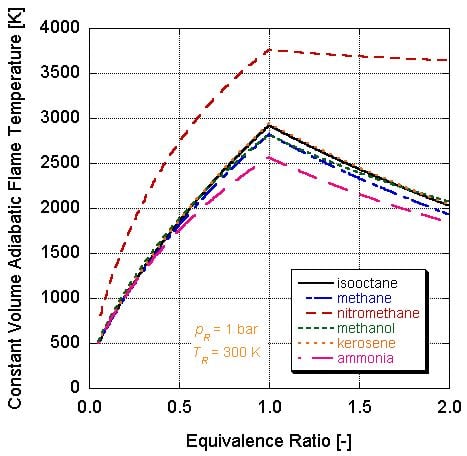

This can get very laden with terminology that is not easily understandable, but I'll try.. With ICE, flame temp knowledge is only important in order to understand the risks of running an engine too lean. Without being properly designed (and tuned) for lean AFR, ICE's will self destruct - slowly or quickly.. This destruction is due to over-temping the components in and around the combustion chamber (valves, rings, squish area, and any/all components with "sharp" edges..)

Proper performance AFR (fueling) will strike a balance between component cooling and power production. Too rich kills power just as much as too lean - but does so without over-temping the components, in fact, it overly cools the components...

Flame Front Speed at various AFR: This is the "holy grail" knowledge for exacting ANY balance of performance/cooling/economy that one may want. This knowledge will allow for proper experimentation, on a given engine design, to find the fueling curve (and AFR's) that produce a desired result. Unfortunately, this knowledge requires a great deal of research, and foundational understanding, to acquire - for instance, try to find flame front speed charts/research for our current fuel (E10). It is "all but" impossible. Just when you think you've "got it", you realize the test/chart was performed with E0 (straight gasoline) , and therefore useless.. There are other ways to determine this data... But for us here, I can provide this knowledge to anyone that wants it.

The overview for achieving best performance is this: Use an AFR that provides the fastest flame front (therefore propagation) for a particular engine, and ignite that AFR at a point where the maximum pressure is obtained at 12-17 degrees ATDC. The best point (ATDC) is dependent on the valve timing events and detonation characteristics of the combustion chamber.

Notes: Tuning shops do not know this stuff and do not employ an understanding of thermodynamics. They simply deploy a "tuning recipe" to any/all customer bikes - producing "cookie cutter" tunes regardless of make or model.. While this process usually produces better driveability and performance - especially on bikes with performance add-ons - it is in no way an attempt to produce top performance with a given engine and mod combo..

Proper performance AFR (fueling) will strike a balance between component cooling and power production. Too rich kills power just as much as too lean - but does so without over-temping the components, in fact, it overly cools the components...

Flame Front Speed at various AFR: This is the "holy grail" knowledge for exacting ANY balance of performance/cooling/economy that one may want. This knowledge will allow for proper experimentation, on a given engine design, to find the fueling curve (and AFR's) that produce a desired result. Unfortunately, this knowledge requires a great deal of research, and foundational understanding, to acquire - for instance, try to find flame front speed charts/research for our current fuel (E10). It is "all but" impossible. Just when you think you've "got it", you realize the test/chart was performed with E0 (straight gasoline) , and therefore useless.. There are other ways to determine this data... But for us here, I can provide this knowledge to anyone that wants it.

The overview for achieving best performance is this: Use an AFR that provides the fastest flame front (therefore propagation) for a particular engine, and ignite that AFR at a point where the maximum pressure is obtained at 12-17 degrees ATDC. The best point (ATDC) is dependent on the valve timing events and detonation characteristics of the combustion chamber.

Notes: Tuning shops do not know this stuff and do not employ an understanding of thermodynamics. They simply deploy a "tuning recipe" to any/all customer bikes - producing "cookie cutter" tunes regardless of make or model.. While this process usually produces better driveability and performance - especially on bikes with performance add-ons - it is in no way an attempt to produce top performance with a given engine and mod combo..

#14

Feel free to PM me with as much technical detail as the subject may warrant, if you don't want to do so publicly. I struggled some, but thoroughly enjoyed my college courses in thermodynamics, so much so that I went and read Carnot's seminal work on the subject years after college. I do think your last gives me a place to start studying the subject though.

#15

Add in Fluid Dynamics (especially CFD), and a peep can begin to "see" the world of ICE performance in a totally new way.. The interconnections become the primary target for attention. E.G. What are the ramifications of a 351 piston/bore to the existing combustion chambers' burn characteristics - and what are the effects concerning a 351 respiring through the 250 intake/exhaust tracts + 250 cams events..?

Anyway, perhaps you should start by determining (for yourself) what you believe is E10 stoich, as even this simple data point is extremely difficult to determine through research.. Hint: We all know 14.7x is stoich for E0, E10 is significantly lower (numerically).. Then consider the ramifications of measuring E10 AFR's with E0 calibrated instruments. Hint: A reading of 12.8 : 1 is NOT an "actual" 12.8 : 1 in the combustion chamber, when the fuel is E10 and the instrument is calibrated for E0.. I will add that ALL DJ dyno's are calibrated E0 - as well as practically all AFR meters ! Do not despair over the E0 vs E10 calibrated instruments - use the readings they produce in the usual way, but just know that the actual AFR is quite a bit richer than what is showing..

You should determine what you believe are E10 (as shown on E0 instruments) values for : Lean Best TRQ (LBT) , Rich best TRQ (RBT) , and Mean Best TRQ (MBT) ...

My "take": Using E0 instruments, max WOT performance potential for most ICE can be found between 12.6 and 13.0 AFR. While a starting point must be chosen based on an analysis of the engine in front of you, 12.75 :1 is usually a good 1st choice for engines that have stock WOT fueling of 12.0 - 13.0 as the existing ignition scheme will not be running too far "out of spec" with 12.75 (Remember, flame front speed for a given chamber and AFR will determine when the AF must be ignited. And 12.75 is a faster flame than 12.0 and 13.0...)

How bout I let the above be enough for now,,,?

Anyway, perhaps you should start by determining (for yourself) what you believe is E10 stoich, as even this simple data point is extremely difficult to determine through research.. Hint: We all know 14.7x is stoich for E0, E10 is significantly lower (numerically).. Then consider the ramifications of measuring E10 AFR's with E0 calibrated instruments. Hint: A reading of 12.8 : 1 is NOT an "actual" 12.8 : 1 in the combustion chamber, when the fuel is E10 and the instrument is calibrated for E0.. I will add that ALL DJ dyno's are calibrated E0 - as well as practically all AFR meters ! Do not despair over the E0 vs E10 calibrated instruments - use the readings they produce in the usual way, but just know that the actual AFR is quite a bit richer than what is showing..

You should determine what you believe are E10 (as shown on E0 instruments) values for : Lean Best TRQ (LBT) , Rich best TRQ (RBT) , and Mean Best TRQ (MBT) ...

My "take": Using E0 instruments, max WOT performance potential for most ICE can be found between 12.6 and 13.0 AFR. While a starting point must be chosen based on an analysis of the engine in front of you, 12.75 :1 is usually a good 1st choice for engines that have stock WOT fueling of 12.0 - 13.0 as the existing ignition scheme will not be running too far "out of spec" with 12.75 (Remember, flame front speed for a given chamber and AFR will determine when the AF must be ignited. And 12.75 is a faster flame than 12.0 and 13.0...)

How bout I let the above be enough for now,,,?

Last edited by Klxster; 10-29-2019 at 11:26 PM.

#16

Since I "hit" on an important issue - without explaining anything about it - I will add that "below a certain value" richer AFR's burn slower and slower. Also, above a certain value, leaner AFR's burn slower and slower.. An ignition point (scheme) that stays the same, but becomes too soon or too late for the AFR (and it's attending flame propagation speed) currently in use, must be considered.

#17

When you know the answer to this question, and why, you are "well on your way"...

Given stock ignition and fueling, on an engine, which has a WOT AFR of 12.1 : 1 ( not uncommon BTW ..) , what may be the ramifications of raising the WOT AFR to 12.75 : 1 ?

Given stock ignition and fueling, on an engine, which has a WOT AFR of 12.1 : 1 ( not uncommon BTW ..) , what may be the ramifications of raising the WOT AFR to 12.75 : 1 ?

Last edited by Klxster; 10-30-2019 at 06:51 PM.

#18

Since I am on a roll about becoming "woke" (lol) with ICE performance, never allow prevailing propaganda/dogma to infect your mind - If you can't justify a position or a posture with fact, research it until you can. Powerful forces have employed propaganda for many decades concerning many things related to ICE performance. Once "awoken", it becomes clear why this is...

For instance: Propaganda/dogma has the masses believing EPA dictates fueling ( including high and WOT fueling) . Therefore, stock tunes are all lean and inferior.. This is totally false ! And here is how I became "woke" on this subject: After seeing enough charts, on stock bike testing, that clearly indicated very/overly rich WOT fueling, I had to reconcile the facts with the dogma (The dogma that stock tuning is too lean because of the EPA..) I researched the EPA procedures for certifying an ICE's emissions.... A week later, I had completed the analysis - the end of this story is that the EPA does not test for, nor care about, all ops above "moderate" accelerations - and steady state running above 47mph(IIRC). All fueling / ignition configurations for high and WOT ops are solely at the discretion of the manufacturer !!! Closed loop and closed loop ops (EFI) are a "thing" because they keep the engine lean for only the EPA testing envelope !!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Now we do not know how many bikes are running overly rich stock fueling because this data is, mysteriously, extremely rare ... You need multiple independent, verifiable, dyno testing results, on stock bikes, with the AFR chart included (quite rare) with the power charts, and all of these charts "published" for all to see.. Every time "we" manage to acquire this data/research on a particular bike, we find overly rich OEM fueling for high and WOT ops !!!!! It is clear that OEM's choose to error on the side of component protection (overly rich AFR protects components - remember?) rather than maximum performance !!!!!

If you ask how you can determine anything from dyno testing/charts, you are "infected" with another dogma/propaganda. Powerful forces, over many decades, have worked hard to try to make everyone believe that dyno data is only applicable to A motorcycle on THE day it was tested. And that no "data accumulations and deductions" about a bike can be made by amassing dyno charts on a bike.. This is also completely false ! Once you know/learn about how to identify trustworthy charts, you can "collect them", from around the world and throughout time, and draw accurate conclusions from their data...

For instance: Propaganda/dogma has the masses believing EPA dictates fueling ( including high and WOT fueling) . Therefore, stock tunes are all lean and inferior.. This is totally false ! And here is how I became "woke" on this subject: After seeing enough charts, on stock bike testing, that clearly indicated very/overly rich WOT fueling, I had to reconcile the facts with the dogma (The dogma that stock tuning is too lean because of the EPA..) I researched the EPA procedures for certifying an ICE's emissions.... A week later, I had completed the analysis - the end of this story is that the EPA does not test for, nor care about, all ops above "moderate" accelerations - and steady state running above 47mph(IIRC). All fueling / ignition configurations for high and WOT ops are solely at the discretion of the manufacturer !!! Closed loop and closed loop ops (EFI) are a "thing" because they keep the engine lean for only the EPA testing envelope !!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Now we do not know how many bikes are running overly rich stock fueling because this data is, mysteriously, extremely rare ... You need multiple independent, verifiable, dyno testing results, on stock bikes, with the AFR chart included (quite rare) with the power charts, and all of these charts "published" for all to see.. Every time "we" manage to acquire this data/research on a particular bike, we find overly rich OEM fueling for high and WOT ops !!!!! It is clear that OEM's choose to error on the side of component protection (overly rich AFR protects components - remember?) rather than maximum performance !!!!!

If you ask how you can determine anything from dyno testing/charts, you are "infected" with another dogma/propaganda. Powerful forces, over many decades, have worked hard to try to make everyone believe that dyno data is only applicable to A motorcycle on THE day it was tested. And that no "data accumulations and deductions" about a bike can be made by amassing dyno charts on a bike.. This is also completely false ! Once you know/learn about how to identify trustworthy charts, you can "collect them", from around the world and throughout time, and draw accurate conclusions from their data...

Last edited by Klxster; 10-30-2019 at 07:42 PM.

#19

And another dogma/propaganda that dyno charts are the only answer. Seems the work was done for decades before computers and instrumentation, using evidence of correct jetting by people being able to make carburetors work properly. Of course they kept information cataloged for future reference before there were spread sheets. Granted they worked in a range of function as well. But then again hard jetting does too, Jets are only available in specific sizing, whether you need one in between or not. Often times their work has been proven out by dynos and spreadsheets and most importantly by riders riding. When results are proven to work there is no need to reinvent the wheel. Riders riding in varying conditions don't have time to do AFR testing and multiple jetting changes, they need to get in the ball park in one shot to keep rolling, not to do continuous jetting changes to meet an optimum. You often gave information on jetting that worked as have others. No need for every individual to repeat all the work, by AFR meter reading or by other methods. You and others have graciously helped riders get their bikes within very functional operation ranges. If it is estimated a rider needs to go two ranges richer at a given point then that's what they should do. Not spend a couple days trying to hit the nth degree of perfection.

I'm sure you will likely say that I am wrong, and that's fine, but it seems tuning was going on long before instrumentation and computers. Granted some was destructive testing although not really intended to be so, but it happened. There were riders jetting fat then dropping back until running adequately clean to avoid running lean and burning a piston or seizure. Records show such for those who were tuning on the edge and needed to keep track. Others just ran fat. he instrumentation makes it easier and able to be recorded and cataloged in spreadsheet, which is good. It isn't black magic and the shared results can meet needs for the masses either way.

As for the EPA thing, makes me curious. You are saying they do deal with run conditions 47 mph and down, so they do cause some of the lean situation in those lower ranges, like that dealt with by the pilot circuit and probably needle jet and jet needle, right? Not to mention noise, which also includes intake noise, right? So choking down for noise with a restrictive snorkel reduces flow and can cause excessively rich mix at higher rpm due to restricted air flow, correct?

Much of what you say makes plenty of sense, I just wish it didn't seem like you are talking down to riders, makes it seem like you believe we are inferior. Many of us are not. We just don't have time, money, or desire to do all the fine tuning to the nth degree. So they go with what will work for the circumstances within reasonable means. Count me among them.

I'm sure you will likely say that I am wrong, and that's fine, but it seems tuning was going on long before instrumentation and computers. Granted some was destructive testing although not really intended to be so, but it happened. There were riders jetting fat then dropping back until running adequately clean to avoid running lean and burning a piston or seizure. Records show such for those who were tuning on the edge and needed to keep track. Others just ran fat. he instrumentation makes it easier and able to be recorded and cataloged in spreadsheet, which is good. It isn't black magic and the shared results can meet needs for the masses either way.

As for the EPA thing, makes me curious. You are saying they do deal with run conditions 47 mph and down, so they do cause some of the lean situation in those lower ranges, like that dealt with by the pilot circuit and probably needle jet and jet needle, right? Not to mention noise, which also includes intake noise, right? So choking down for noise with a restrictive snorkel reduces flow and can cause excessively rich mix at higher rpm due to restricted air flow, correct?

Much of what you say makes plenty of sense, I just wish it didn't seem like you are talking down to riders, makes it seem like you believe we are inferior. Many of us are not. We just don't have time, money, or desire to do all the fine tuning to the nth degree. So they go with what will work for the circumstances within reasonable means. Count me among them.

Last edited by klx678; 10-31-2019 at 02:12 AM.

#20

I will try to not become ensnared by the above. I'll just expand on what I've already said: A position, posture, or opinion, should be supported via data and/or overwhelming evidence. I can provide such for my opinions, postures, and positions for anyone embarking on a journey of "improvement"... I am unaware of any proof or evidence of a prevalent dogma/propaganda that serves to tout that "dyno charts are the only answer" .. The answers for paragraph 3 are : Yes, Yes, No (all aspects of the intake tract are taken into consideration when the OEM sets up the carb. Overfueling at high RPM and passing noise testing are not related.)

I once told you I'd be your friend for life if you would remove your public references where you instruct peeps to install wire (coat hanger, etc) onto the exhaust cam, on the KACR flyweights..

So, thanks for your post friend. I'm happy to help you with any endeavor..

I once told you I'd be your friend for life if you would remove your public references where you instruct peeps to install wire (coat hanger, etc) onto the exhaust cam, on the KACR flyweights..

So, thanks for your post friend. I'm happy to help you with any endeavor..

Last edited by Klxster; 10-31-2019 at 02:45 AM.