FMF Q4 woes, exhaust leaks and strippped screw.

#1

I'm having major problems with my FMF Q4 Pipe...probably mostly due to my own fault.

Firstly, I can't get a proper seal between the Slip-on and the Stock header.

I've tried to use firegum, but it doesnt really seem to do the trick. I poured soapy water on it and I see bubbles from the soap, which means that there is a leak.

Furthermore, I repacked the pipe and that has caused the whole thing to be even more leaky. It no longer seals tight where the pipe comes apart. Again, I used firegum and stopped most if it, but when I put soapy water on it, it starts bubbling up again...

So, what I am asking:

1) Please share your experiences from your own slip-on installation...especially with the stock header. What am I doing wrong?

2) Is there an alternative to Firegum? It looks ugly as hell with all that white stuff all over my pipe and it doesnt seem to be solving the problem either way.

3) I also managed to strip one of the bolt sockets on the thin aluminum of the pipe, very annoying and I am not sure what I can do about this. Any suggestions?

Firstly, I can't get a proper seal between the Slip-on and the Stock header.

I've tried to use firegum, but it doesnt really seem to do the trick. I poured soapy water on it and I see bubbles from the soap, which means that there is a leak.

Furthermore, I repacked the pipe and that has caused the whole thing to be even more leaky. It no longer seals tight where the pipe comes apart. Again, I used firegum and stopped most if it, but when I put soapy water on it, it starts bubbling up again...

So, what I am asking:

1) Please share your experiences from your own slip-on installation...especially with the stock header. What am I doing wrong?

2) Is there an alternative to Firegum? It looks ugly as hell with all that white stuff all over my pipe and it doesnt seem to be solving the problem either way.

3) I also managed to strip one of the bolt sockets on the thin aluminum of the pipe, very annoying and I am not sure what I can do about this. Any suggestions?

#2

2) Is there an alternative to Firegum? It looks ugly as hell with all that white stuff all over my pipe and it doesnt seem to be solving the problem either way.

I shouldn't of bothered, like you say it leaves a mess and doesn't do anything to prevent air leakage. I scrubbed the firegum off the pipe and unfortunately left with a leak. I'm sure there will be other products on the market that will correct the issue better than the firegum, see what other recommend.

3) I also managed to strip one of the bolt sockets on the thin aluminum of the pipe, very annoying and I am not sure what I can do about this. Any suggestions?

#6

Hey guys and thanks for the feedback.

I already bended the bracket, so that is not the issue. There is no problem getting the pipe mounted, its just the fact that its leaking thats annoying me.

@Brieninsac

Yeah I am using high temp sealant. I didnt let it cure more than a few hours last time, maybe thats my problem? Explain your method to me? Do you warm up the bike first and then apply it? or do you warm it up after application? As far as I understand it, it needs heat for curing, but the exhaust gas blows right through the sealant if you try to heat up the system before its cured.

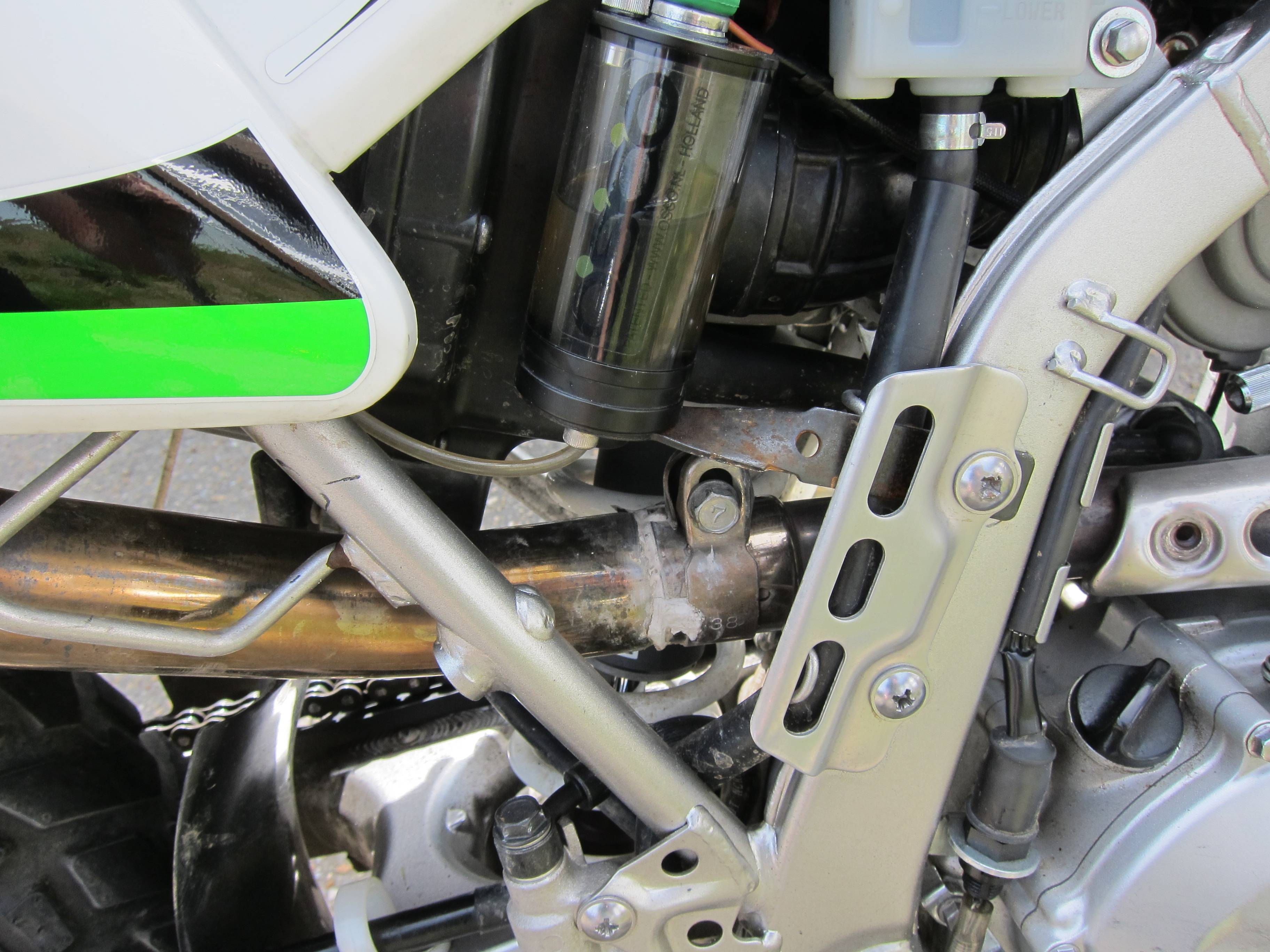

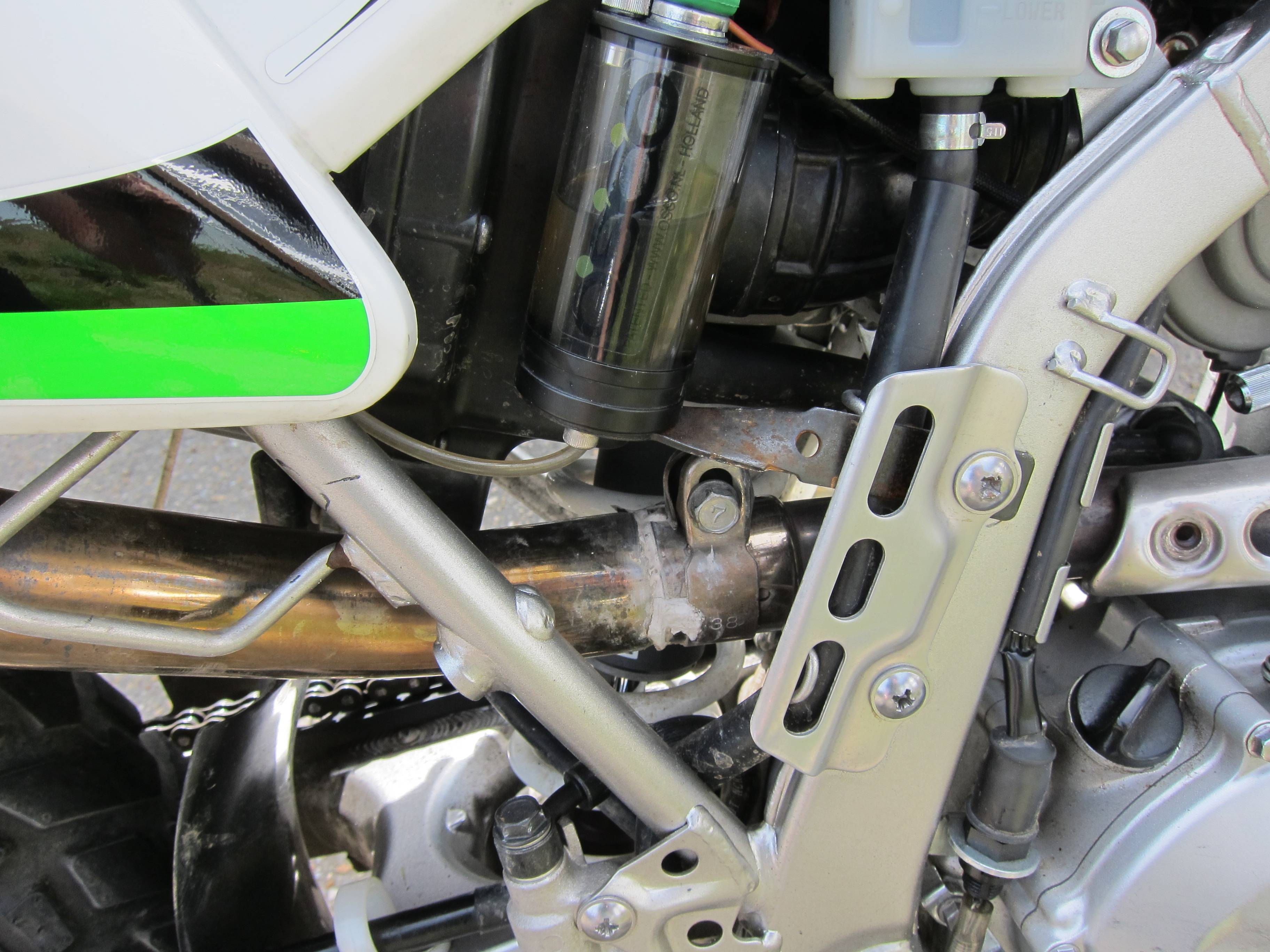

Anyway, here are some pictures as requested.

The white stuff the the sealant and you can also see two screws missing. The screws are almost the worst part of my problem. Any suggestions?

Note the forth pic also, its pretty much leaky all the way around.

I already bended the bracket, so that is not the issue. There is no problem getting the pipe mounted, its just the fact that its leaking thats annoying me.

@Brieninsac

Yeah I am using high temp sealant. I didnt let it cure more than a few hours last time, maybe thats my problem? Explain your method to me? Do you warm up the bike first and then apply it? or do you warm it up after application? As far as I understand it, it needs heat for curing, but the exhaust gas blows right through the sealant if you try to heat up the system before its cured.

Anyway, here are some pictures as requested.

The white stuff the the sealant and you can also see two screws missing. The screws are almost the worst part of my problem. Any suggestions?

Note the forth pic also, its pretty much leaky all the way around.

#7

I have an fmf header now but when I had the stock head pipe I used high temp black silicone and let it dry overnight and had no leaks. Used the same stuff when I went to the FMF header and had no issues, the silicone excess can be wiped off before it dries.

#8

As for the stripped fasteners, get one thread size larger screws (self tapping if possible, otherwise drill the stripped thread and tap to the next size) drill out the can to clear the new fastener (the part being held to the cone), then put in the screws - carefully, don't strip it again. Maybe use button head socket screws (aka allen head).

#10

Rivets will work, but if they start to loosen they cannot be tightened. They have to be drilled out to repack silencers too. That is why the screws were suggested... that and that's how both my pipes are built.