Advice on electrics for the KLX.

#21

I've only had one problem with the e-start, and it was my fault. I stopped went to restart nothing. Turned out the bolt that holds the battery bracket closed fell out ( I don't always go over all the fasteners every time I ride ). This caused battery cable bolts to come loose somehow and both the cables came off, I zip tied them back on but the connection wasn't good enough to crank the starter. But it was really easy to push start it. I did it first gear. I pushed it in neutral got it going hopped on popped it in gear let out the clutch and away she went. This was on a hard packed dirt road though. If it was deep sand that would be a different story. Now if you want to know a hard bike to push start try an 01 YZ 426.

#22

As I don't have a kickstart on my 07 KLX250R I want to take a few steps to ensure the bike starts on the battery every time. One thing concerning me is the headlight being ON as soon as the ignition key is turned, before the bike is started. As I understand it, the headlight draws about 70 watts. I would prefer it if the light was not ON when I started the bike ensuring all available power from the battery is going to the starter when i thumb the button. Can anyone detail where I can fit a switch to isolate the headlight making it possible to turn the lights on and off at will. I'm planning some trips further out in the bush and feel this is a cheap mod that is worth doing seeing as I rely 100% on the battery charge to start the bike. I know that the cold can sap the power of a battery very easily. The outback and desert can get down to 0 oC and even freeze at night. I just want those first turns of the motor in the morning to count.

Advice taken from a mate who suffered a very similar problem that dogged his recent outback adventure. Solved it with cable ties, tape and a few bits of wire. I'd just like to do a more professional job.

Any ideas?

Advice taken from a mate who suffered a very similar problem that dogged his recent outback adventure. Solved it with cable ties, tape and a few bits of wire. I'd just like to do a more professional job.

Any ideas?

This solution was the easiest and cheapest way of meeting my objectives. I have a switchable headlight that gives me the ability to turn it off when I start the bike.

The solution is not 100% as I now only have the high beam option when I need to run a headlight. To be honest, that doesn't bother me. I chose to keep the high not the dip for obvious reasons.

The bonus is the dipped beam is easily wired back into operation on the trail if needed. In fact, if the high beam blows it will be quicker to reconnect the dipped beam than fit a new bulb.

Happy.

Last edited by WestOzKLX; 08-19-2009 at 02:42 PM.

#23

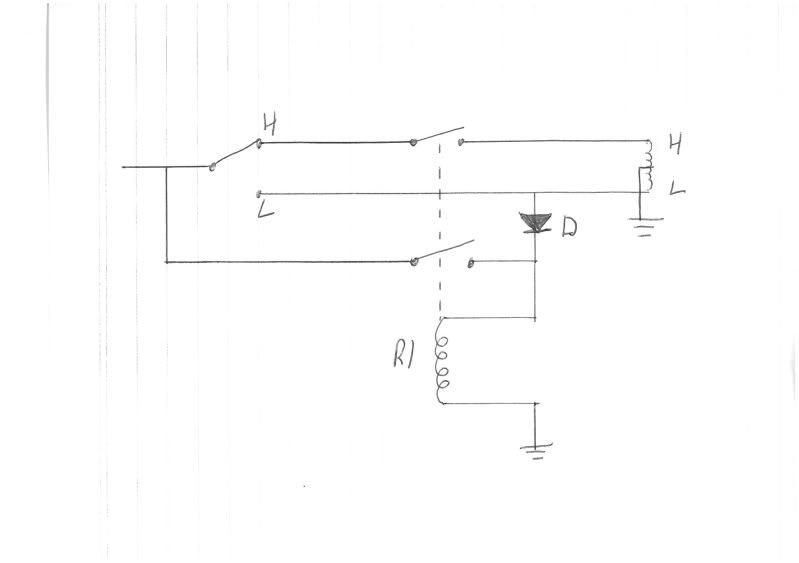

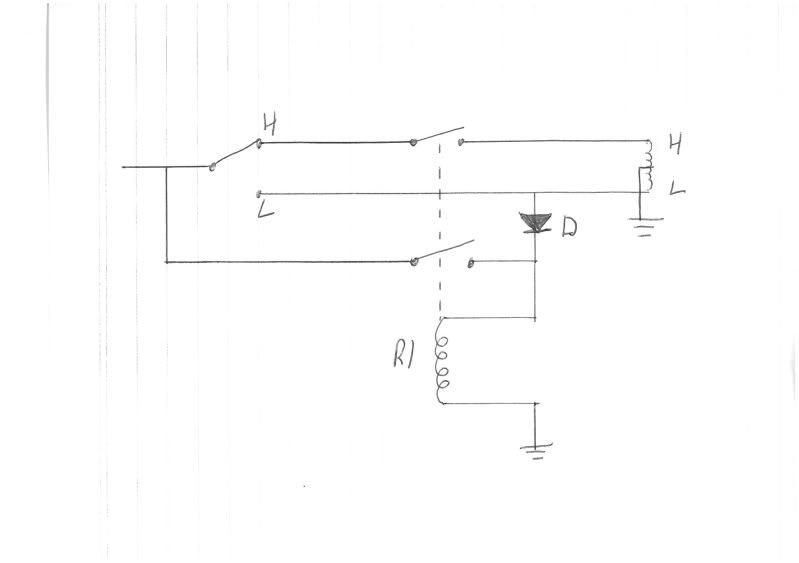

OK, I have thought about my original way of controlling the headlight without the need for an external switch and came up with this.

Firstly, this circuit is waayyyy simpler than it looks.

1 relay($5). 1 diode(10c) and 1 hour(free)

Using this circuit when the hi/low switch is in the hi position the headlight will not light up when the ignition is turned on.

The headlight will light up low when the hi/low switch is switched to low.

The relay will now be latched and will stay latched until the ignition is turned off.

So when the switch is switched back to hi, the headlight will work as normal.

Once the relay is activated the headlight will work as normal with both beams available.

Benifits are no need to mount a switch and both beams will still work as normal.

Previously I used the horn button to activate the relay.

I believe this is an improvement.

Just thought I'd throw it out there

Firstly, this circuit is waayyyy simpler than it looks.

1 relay($5). 1 diode(10c) and 1 hour(free)

Using this circuit when the hi/low switch is in the hi position the headlight will not light up when the ignition is turned on.

The headlight will light up low when the hi/low switch is switched to low.

The relay will now be latched and will stay latched until the ignition is turned off.

So when the switch is switched back to hi, the headlight will work as normal.

Once the relay is activated the headlight will work as normal with both beams available.

Benifits are no need to mount a switch and both beams will still work as normal.

Previously I used the horn button to activate the relay.

I believe this is an improvement.

Just thought I'd throw it out there

Last edited by neilaction; 08-20-2009 at 01:12 AM.

#24

Wow, thanks for the info guys.

I am going to use this info to disconnect the headlight to run an accessory plug when required. I carry a small palm sized electric air pump with my spare inner tube in case of a flat on my Klr 650. Want to do the same for the Klx250s, but worry about discharging the battery while filling the tire. This will not happen running the motor with the headlight disconnected while filling the tire.

I am going to use this info to disconnect the headlight to run an accessory plug when required. I carry a small palm sized electric air pump with my spare inner tube in case of a flat on my Klr 650. Want to do the same for the Klx250s, but worry about discharging the battery while filling the tire. This will not happen running the motor with the headlight disconnected while filling the tire.

#25

OK, I have thought about my original way of controlling the headlight without the need for an external switch and came up with this.

Firstly, this circuit is waayyyy simpler than it looks.

1 relay($5). 1 diode(10c) and 1 hour(free)

Using this circuit when the hi/low switch is in the hi position the headlight will not light up when the ignition is turned on.

The headlight will light up low when the hi/low switch is switched to low.

The relay will now be latched and will stay latched until the ignition is turned off.

So when the switch is switched back to hi, the headlight will work as normal.

Once the relay is activated the headlight will work as normal with both beams available.

Benifits are no need to mount a switch and both beams will still work as normal.

Previously I used the horn button to activate the relay.

I believe this is an improvement.

Just thought I'd throw it out there

Firstly, this circuit is waayyyy simpler than it looks.

1 relay($5). 1 diode(10c) and 1 hour(free)

Using this circuit when the hi/low switch is in the hi position the headlight will not light up when the ignition is turned on.

The headlight will light up low when the hi/low switch is switched to low.

The relay will now be latched and will stay latched until the ignition is turned off.

So when the switch is switched back to hi, the headlight will work as normal.

Once the relay is activated the headlight will work as normal with both beams available.

Benifits are no need to mount a switch and both beams will still work as normal.

Previously I used the horn button to activate the relay.

I believe this is an improvement.

Just thought I'd throw it out there

I get the diagram, but where do I solder in the diode? (value?) Where do I fix the diode?

I get the diagram, but where do I solder in the diode? (value?) Where do I fix the diode?Wow, thanks for the info guys.

I am going to use this info to disconnect the headlight to run an accessory plug when required. I carry a small palm sized electric air pump with my spare inner tube in case of a flat on my Klr 650. Want to do the same for the Klx250s, but worry about discharging the battery while filling the tire. This will not happen running the motor with the headlight disconnected while filling the tire.

I am going to use this info to disconnect the headlight to run an accessory plug when required. I carry a small palm sized electric air pump with my spare inner tube in case of a flat on my Klr 650. Want to do the same for the Klx250s, but worry about discharging the battery while filling the tire. This will not happen running the motor with the headlight disconnected while filling the tire.

#26

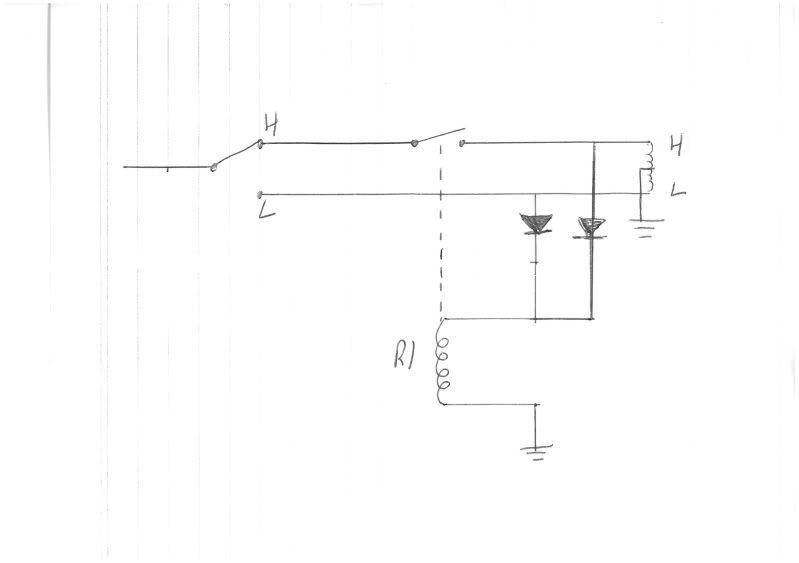

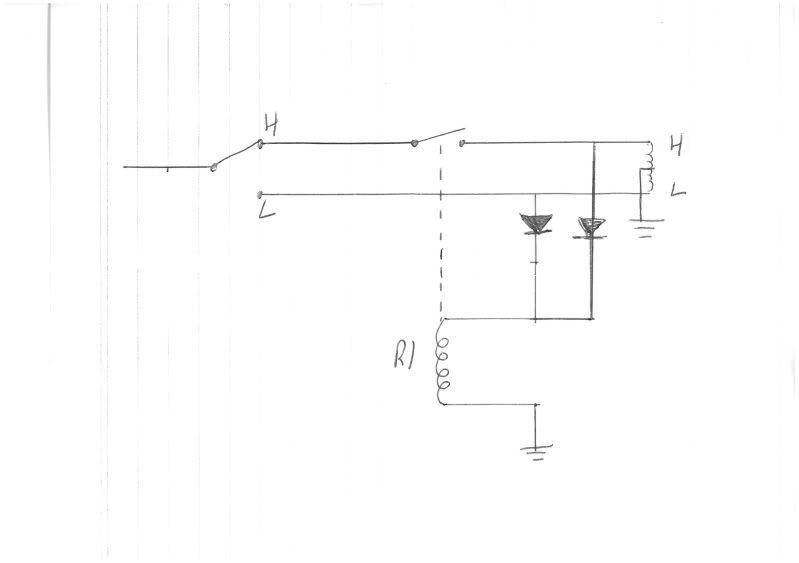

The fairy tale continues WestOz

I had another idea.

I am 99% sure that the hi/low switch is a make before break switch.

Meaning that the hi is turned on before the low is turned off and vica versa.

What that means is I can use the same contacts that will switch the hi beam on to also latch the relay.

It means 1 more isolating diode but they are like 10c

This circuit is an improvement.

Its an improvement because.

a. I can use a general purpose automotive relay as they tend to have only 1 pole. They are also generally water proof.

b. All the wiring changes are confined to the 3 wires that connect to the bulb. Hi, low and ground. There is no need to source a seperate b+ to power the relay.

It will still work as previously described.

The headlight will remain off until the hi/low switch is switched to low.

Then once the relay is activated the hi/low beams will work as normal.

I had another idea.

I am 99% sure that the hi/low switch is a make before break switch.

Meaning that the hi is turned on before the low is turned off and vica versa.

What that means is I can use the same contacts that will switch the hi beam on to also latch the relay.

It means 1 more isolating diode but they are like 10c

This circuit is an improvement.

Its an improvement because.

a. I can use a general purpose automotive relay as they tend to have only 1 pole. They are also generally water proof.

b. All the wiring changes are confined to the 3 wires that connect to the bulb. Hi, low and ground. There is no need to source a seperate b+ to power the relay.

It will still work as previously described.

The headlight will remain off until the hi/low switch is switched to low.

Then once the relay is activated the hi/low beams will work as normal.

#27

I was right in that the hi/low switch is a make before break so the simpler circuit I drew will work OK.

Done.

https://www.kawasakiforums.com/forum...ad.php?t=29896

Done.

https://www.kawasakiforums.com/forum...ad.php?t=29896

#28

The fairy tale continues WestOz

I had another idea.

I am 99% sure that the hi/low switch is a make before break switch.

Meaning that the hi is turned on before the low is turned off and vica versa.

What that means is I can use the same contacts that will switch the hi beam on to also latch the relay.

It means 1 more isolating diode but they are like 10c

This circuit is an improvement.

Its an improvement because.

a. I can use a general purpose automotive relay as they tend to have only 1 pole. They are also generally water proof.

b. All the wiring changes are confined to the 3 wires that connect to the bulb. Hi, low and ground. There is no need to source a seperate b+ to power the relay.

It will still work as previously described.

The headlight will remain off until the hi/low switch is switched to low.

Then once the relay is activated the hi/low beams will work as normal.

I had another idea.

I am 99% sure that the hi/low switch is a make before break switch.

Meaning that the hi is turned on before the low is turned off and vica versa.

What that means is I can use the same contacts that will switch the hi beam on to also latch the relay.

It means 1 more isolating diode but they are like 10c

This circuit is an improvement.

Its an improvement because.

a. I can use a general purpose automotive relay as they tend to have only 1 pole. They are also generally water proof.

b. All the wiring changes are confined to the 3 wires that connect to the bulb. Hi, low and ground. There is no need to source a seperate b+ to power the relay.

It will still work as previously described.

The headlight will remain off until the hi/low switch is switched to low.

Then once the relay is activated the hi/low beams will work as normal.

#29

Plus, the tail light is only 5w.

#30

Then use two standard auto relays (one can operate the other) and break the tail light wire on the subframe somewhere and run it to the headlight housing to the second relay. It may only be a few watts but if your going this far to kill the power consumption before starting, then why not get it all?