How to free stuck or seized brake caliper pistons

#1

I had to rebuild the calipers on my 1994 ZX7R (M1) and the pistons were stuck in both calipers so I decided to document the process on how to free the pistons when they're stuck so, if anyone else has this problem, you have a reference for how to free them.

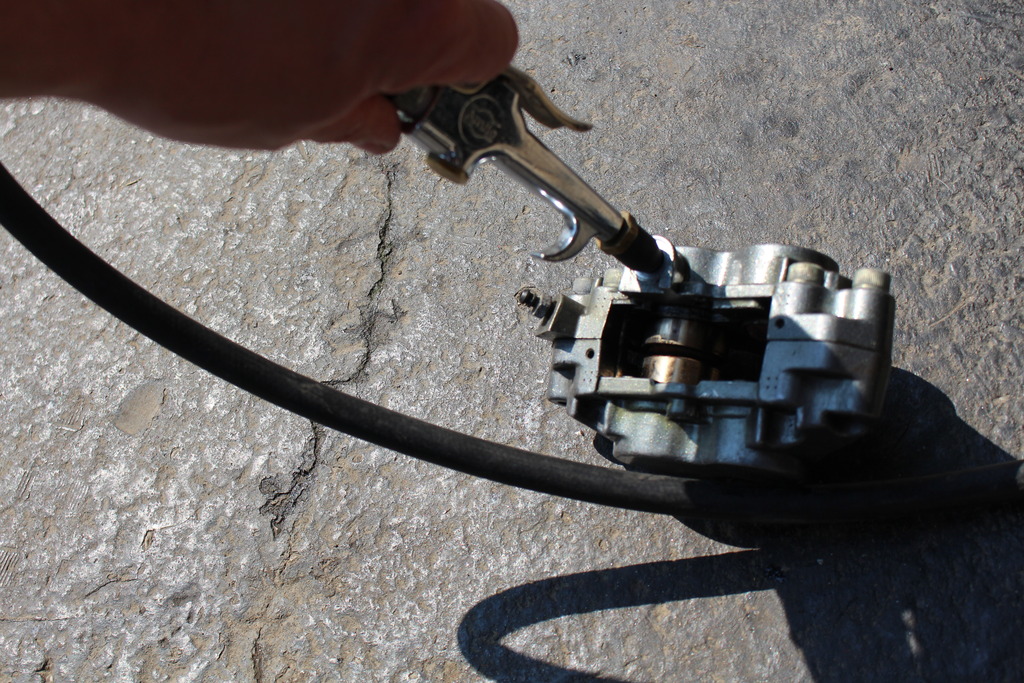

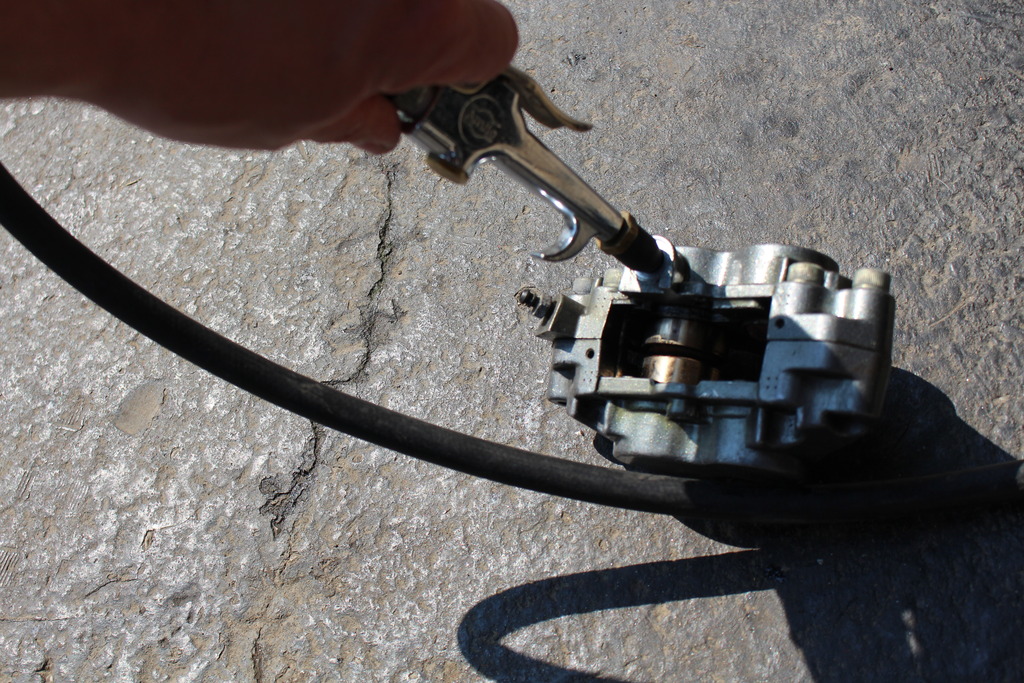

When I started, I pulled the calipers and drained most of the fluid out of them. I say most because you will not get it all out, so expect it to get on everything when you pop the pistons out. Then I put compressed air to the brake line banjo bolt port on the caliper:

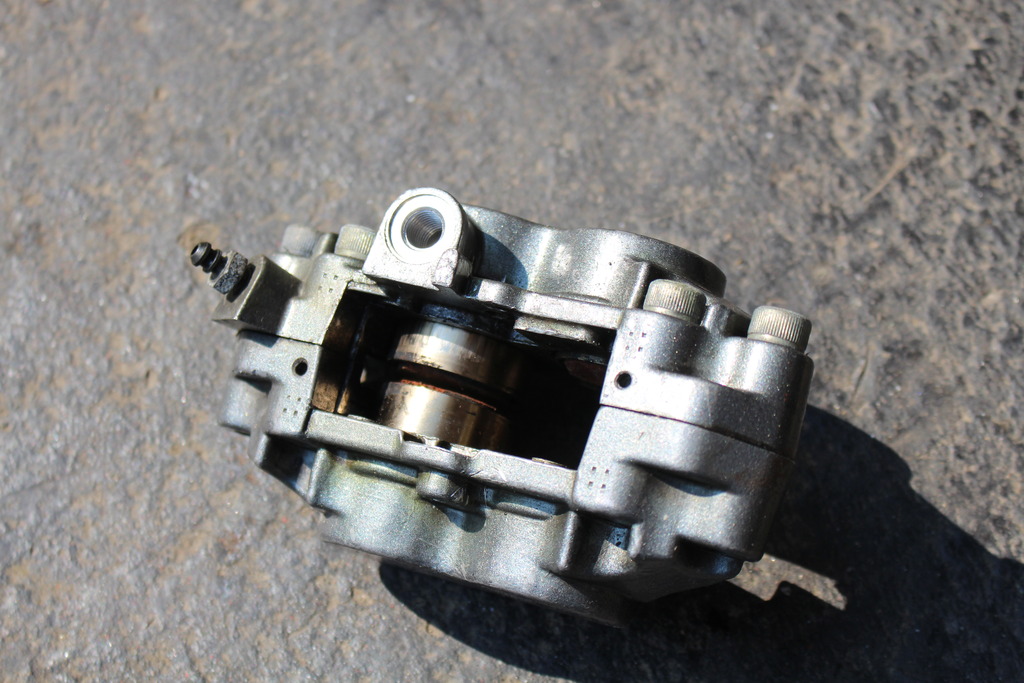

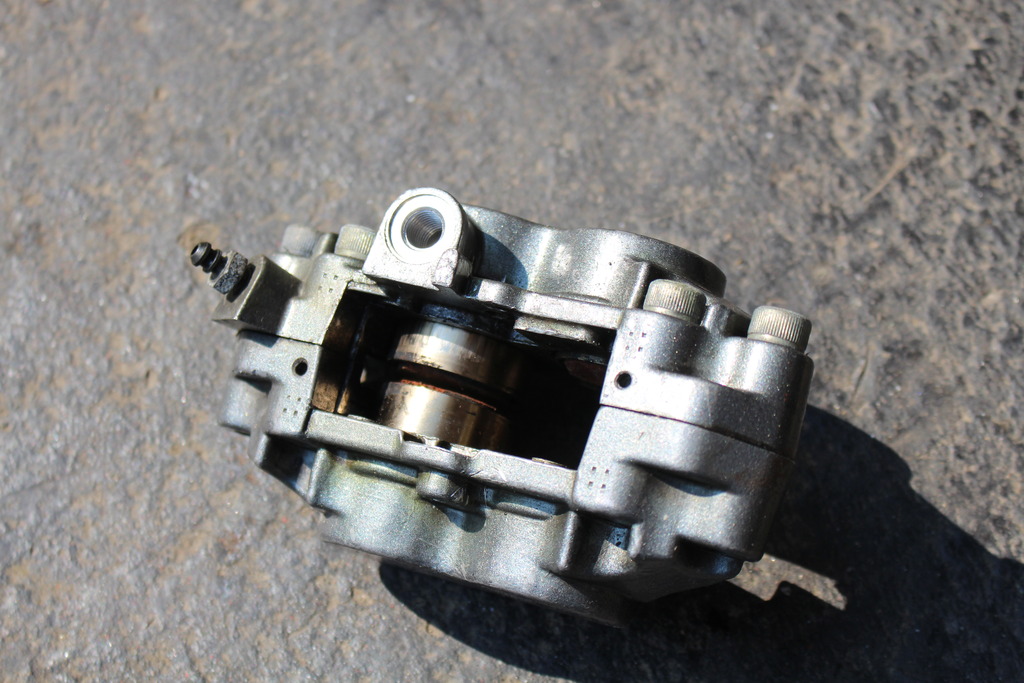

This only freed one piston:

The two large pistons were wedged in their bores and wouldn't move once they pushed out to what you see in the picture. The other small piston didn't move at all.

So I put the caliper in a soft jawed vice and split it apart. I used the soft jaws and a paper towel to keep from damaging the caliper.

There are four bolts that hold the two halves together and, once removed, you can see the corrosion on them.

I put them in an ultrasonic cleaner and it removed most of the corrosion and general nastiness from all the bolts.

Here's the caliper once it's split apart. Notice the 3 pistons are still stuck.

When I started, I pulled the calipers and drained most of the fluid out of them. I say most because you will not get it all out, so expect it to get on everything when you pop the pistons out. Then I put compressed air to the brake line banjo bolt port on the caliper:

This only freed one piston:

The two large pistons were wedged in their bores and wouldn't move once they pushed out to what you see in the picture. The other small piston didn't move at all.

So I put the caliper in a soft jawed vice and split it apart. I used the soft jaws and a paper towel to keep from damaging the caliper.

There are four bolts that hold the two halves together and, once removed, you can see the corrosion on them.

I put them in an ultrasonic cleaner and it removed most of the corrosion and general nastiness from all the bolts.

Here's the caliper once it's split apart. Notice the 3 pistons are still stuck.

#2

On the side without the banjo bolt port you will have to use the internal ports of the caliper to apply compressed air to the backside of the pistons.

To do this, I used a piece of aluminum flat stock that I had laying in the garage. I clamped it over the cross-feed port of the caliper to seal it to stop air flow. I used the old o-ring to seal the port to the aluminum flat stock.

I also plugged the open piston bore to stop air from bypassing the stuck piston. Then I applied air to the open port and the piston shot out like a bullet.

You can see the corrosion on the inside of the piston bore in this photo. That's what was causing my problem; which was stuck pistons in both calipers. I needed to hone the bores to remove the corrosion and rebuild the calipers.

To do this, I used a piece of aluminum flat stock that I had laying in the garage. I clamped it over the cross-feed port of the caliper to seal it to stop air flow. I used the old o-ring to seal the port to the aluminum flat stock.

I also plugged the open piston bore to stop air from bypassing the stuck piston. Then I applied air to the open port and the piston shot out like a bullet.

You can see the corrosion on the inside of the piston bore in this photo. That's what was causing my problem; which was stuck pistons in both calipers. I needed to hone the bores to remove the corrosion and rebuild the calipers.

#3

The other half of the caliper needs both cross-over ports blocked to successfully remove the stuck pistons.

After I blocked the ports I applied air to the banjo bolt port:

I used a plastic bag to wrap around the caliper so it would catch the pistons when they came out. Don't make any mistake here, the pistons literally pop out of their bores with quite a bit of force and they will easily shoot across a room and possibly injure someone. That's why I have the bag. SAFETY FIRST. You may also want to do the whole air application process in a yard so the piston hits soft grass or dirt when it comes out and this will prevent damage to the pistons. But still USE A BAG TO CATCH THE PISTON.

One piston came out:

After I blocked the ports I applied air to the banjo bolt port:

I used a plastic bag to wrap around the caliper so it would catch the pistons when they came out. Don't make any mistake here, the pistons literally pop out of their bores with quite a bit of force and they will easily shoot across a room and possibly injure someone. That's why I have the bag. SAFETY FIRST. You may also want to do the whole air application process in a yard so the piston hits soft grass or dirt when it comes out and this will prevent damage to the pistons. But still USE A BAG TO CATCH THE PISTON.

One piston came out:

#4

This is how the piston looked in the bag.

Now to get the last one out.

Take the piston you just removed and put it back in. Put brake fluid or oil on it to prevent it from getting stuck again and set it up similar to what I have in the picture. The aluminum piece will prevent the freed piston from pushing out so it works to keep all air pressure focused on the stuck piston.

Once air is applied the last stuck piston popped loose.

Now you're free to hone the bores to remove the corrosion:

I hope this helps some of you guys out.

Now to get the last one out.

Take the piston you just removed and put it back in. Put brake fluid or oil on it to prevent it from getting stuck again and set it up similar to what I have in the picture. The aluminum piece will prevent the freed piston from pushing out so it works to keep all air pressure focused on the stuck piston.

Once air is applied the last stuck piston popped loose.

Now you're free to hone the bores to remove the corrosion:

I hope this helps some of you guys out.

#6

Thanks. I think you need to regularly change fluid as the only solution I can think of and you may still have corrosion issues with that.

#8

Thread

Thread Starter

Forum

Replies

Last Post